OBD2 connector repair ought to be easy, but it isn’t. Connectors and terminals aren’t always available, and when they are, it can be very difficult to find the parts you need. Here’s some information that may help you if you’re looking into option to fix your OBD2 connector.

What is the OBD2 connector?

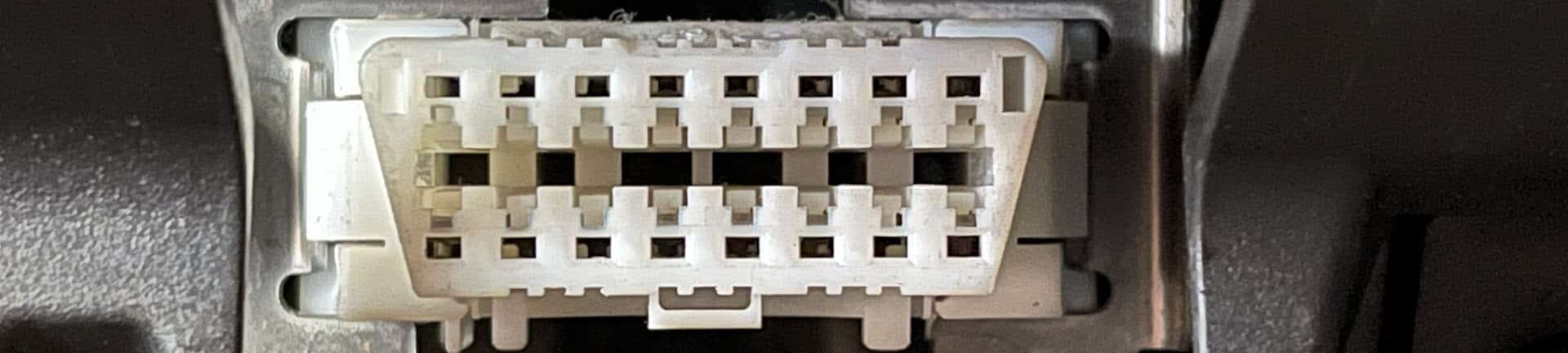

The OBD2 connector is a standardized 16 pin diagnostic interface. Every car model year 1996 or newer has one. It’s really nice because no matter who made the car, a generic OBD2 scanner can get at least some data. I say “some data” because the standard mandates certain data be accessible, but automakers have a lot of available data that’s not included in the OBD2 standard, and isn’t available with a generic scan tool.

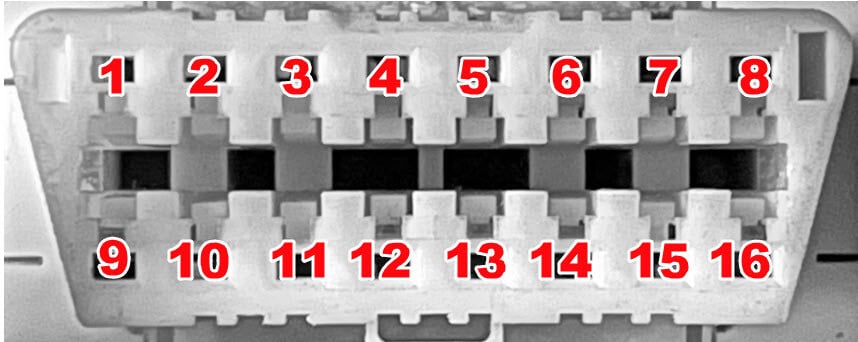

Pin positions

1: Manufacturer’s choice

2 & 10: SAE J1850 (network)

3: Manufacturer’s choice

4: Chassis ground

5: Signal ground

6 & 14: CAN bus high and low (network)

7 & 15: ISO9140 K-Line (network)

8, 9, 11, 12, 13: Manufacturer’s choice

16: Battery positive (key off power)

What gets damaged?

It almost always pin 16. Why? There are a couple of reasons.

First, sometimes the fuse for pin 16 blows. It might be because of a badly-designed aftermarket accessory installed on the port. It might be due to an overload on a different circuit sharing the same fuse. Why would a blown fuse hurt the terminal? It wouldn’t. But some dummy testing for power by jamming a probe into the connector where it doesn’t fit will certainly damage the terminal and maybe the connector as well. The #1 reason for OBD2 connector repair is damage caused by oblivious or heedless people performing tests.

The other reason is aftermarket accessories that use the OBD2 connector – insurance baby-sitting dongles people install for a discount on their premium, aftermarket gauges or data recorders, that sort of stuff. Why am I picking on the aftermarket? Because the engineering and quality control isn’t as good on a lot of it. One issue is oversize male pins on the device stretching out the female terminals in the OBD2 connector. Another problem is devices that draw excessive current from pin 16. Not enough to blow the fuse, but far more than normal and all the time the car is running. The connector was designed to supply power to a scan tool for short periods, not run a current-hogging device all the time.

If OBDII is a standard, all the connectors are the same, right?

Unfortunately, OBD2 connectors are all different. What I mean is that any male OBD2 connector can plug into any female OBD2 connector, but the way the connector is attached to the car and the way the terminals are installed into the connector is different on nearly every car. If you check with a connector supplier, you’ll find pages of possible connectors (the plastic part) and pages of possible terminals (the metal part).

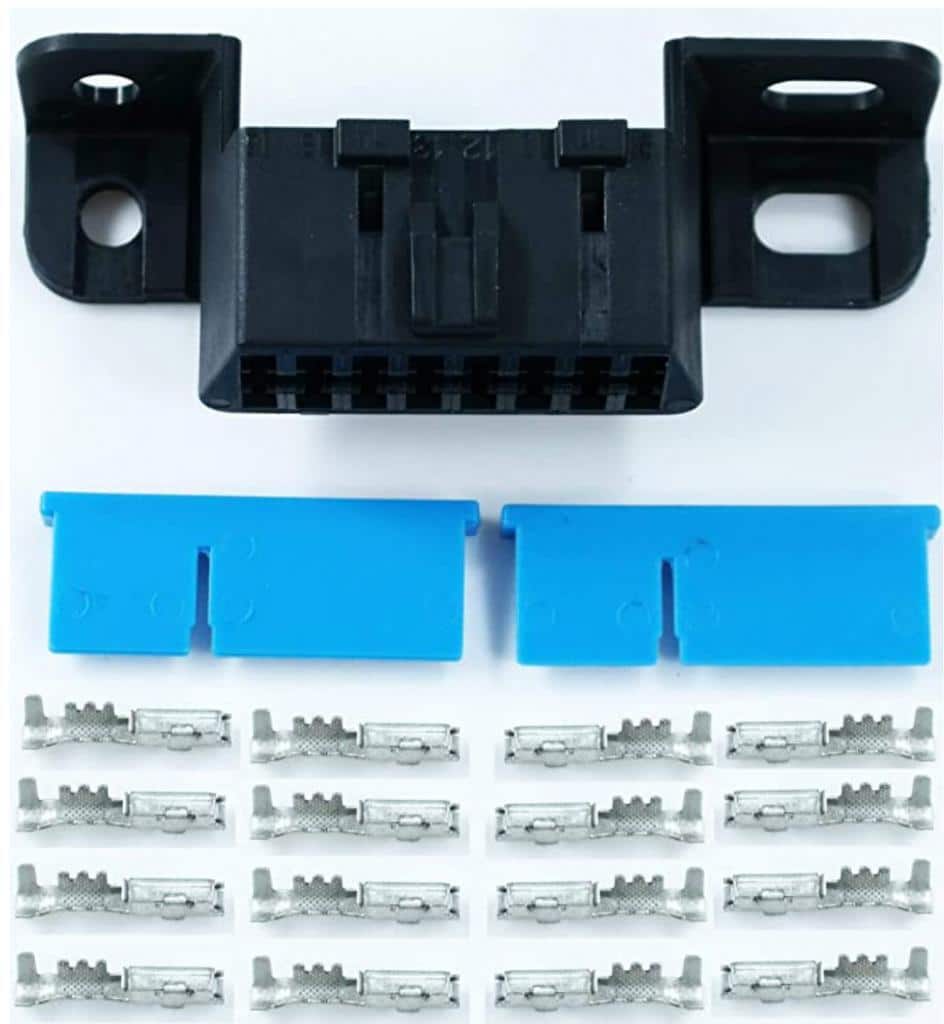

I found a replacement OBD2 connector on Amazon for only $12!

Yeah. We found them too. One issue is the way they connect the car. They won’t fit in the original bracket, so they need to be attached to the lower dash with self tapping screws, which is pretty dodgy and probably won’t last forever. However, if this were the only issue, we might use these connectors. The real problem is the quality of the terminals. The metal is soft and doesn’t spring back like the originals do. Sure, installing one of these will “repair” the car, but for how long.

Let’s say a particular OBD2 connector has 10 terminals installed. Each terminal will take about 3 minutes to install onto a pigtail. Then we’ll need to remove the lower dash to access the wiring (at least 15 minutes including putting it back). Then we’ll need to solder and heat shrink 10 wires which will take around 5 minutes each. At minimum, bit over an hour and a half total. At todays labor rate, about $210 in labor.

My point is this: with the cost involved, it doesn’t make sense to use sub-standard parts. We don’t want to pay to warranty it and our customers won’t want to pay to do it again after the warranty has expired.

Why not just buy the part from the dealer?

This is the best option, but it often quite difficult. Let’s use Toyota as an example since about 40% of the cars we repair are Toyota.

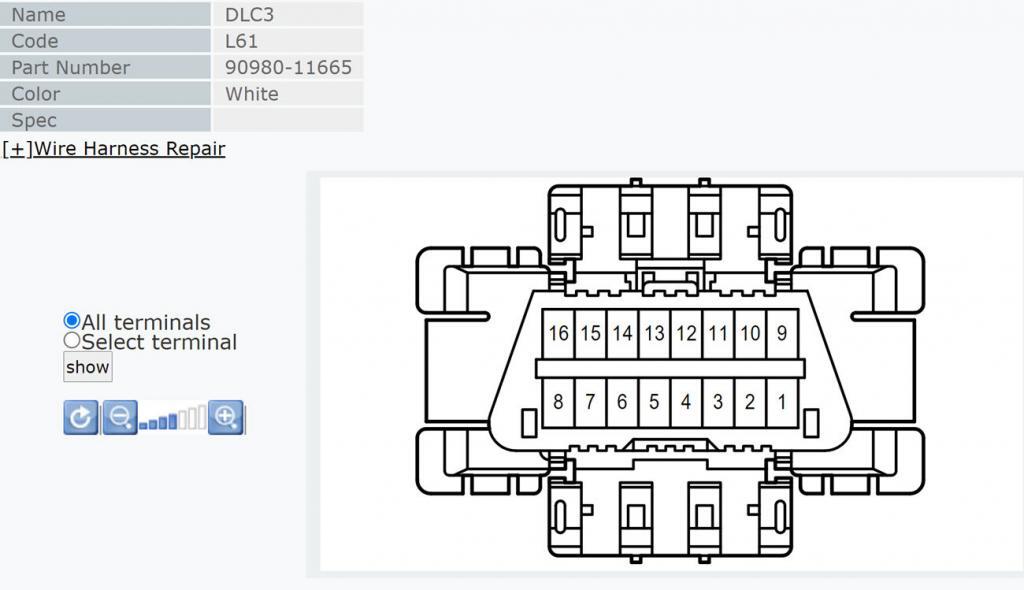

If you call Toyota and ask for a replacement OBDII connector, they’ll say it’s not available. While it’s true it’s not listed in the parts catalog, you can buy the part, but in pieces. The way you find the number is to look at the electrical wiring diagram on TIS. If you click on the OBD2 connector, and then the orange information box, you’ll get a part number for the plastic connector. Very cool.

This one is part number 90980-11665

I actually just recently discovered that connector part number information is also available in older Toyota service information, back before they had electronic wiring diagrams. If you log on to TIS and search for “part number of connectors” you’ll find a document with all of the connector part numbers listed by wiring diagram code.

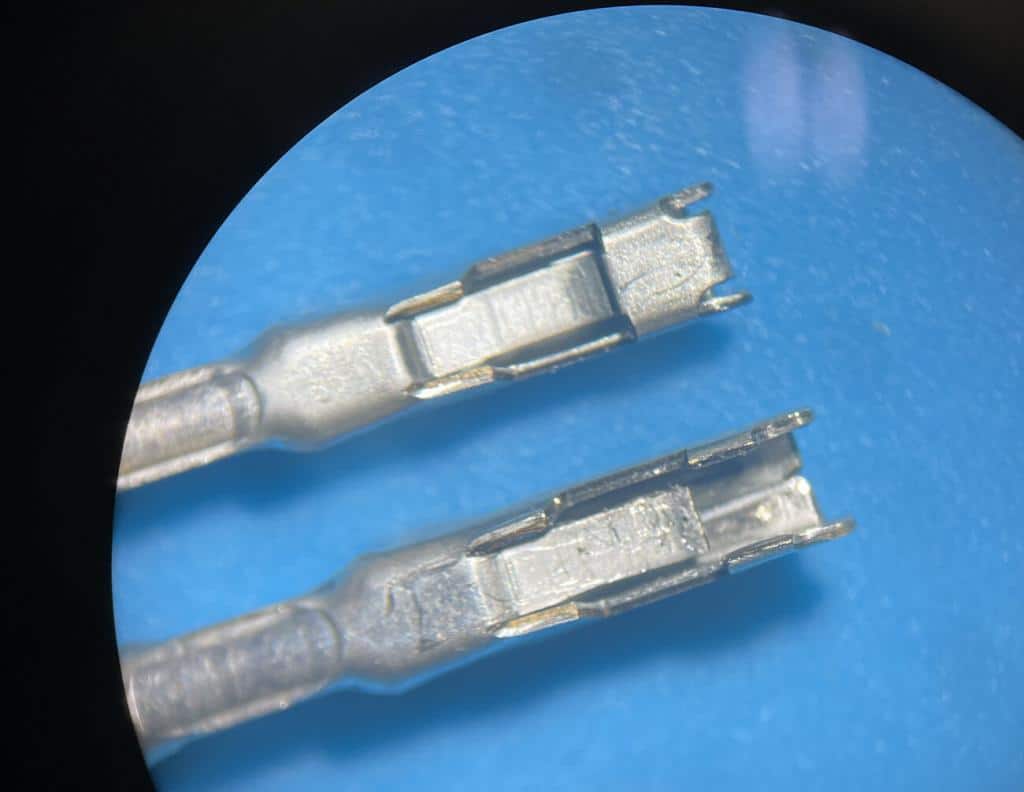

However, that’s only half the battle. You’ll still need the metal terminals. My last OBDII connector repair was a Gen3 Prius. I called our dealer and told them the connector number and the application and asked if they had any way to figure out what terminal would fit. She said, “Probably, but I’m not sure how. I’ll check with the manager and call you back.” We’re good customers and they take care of us. She called back in a while to say the manager couldn’t figure it out either, but he was making some calls and that she asked the shop foreman, and said he “horded” used terminals and if we just needed a couple he’d give them to us. Smart guy, and generous too.

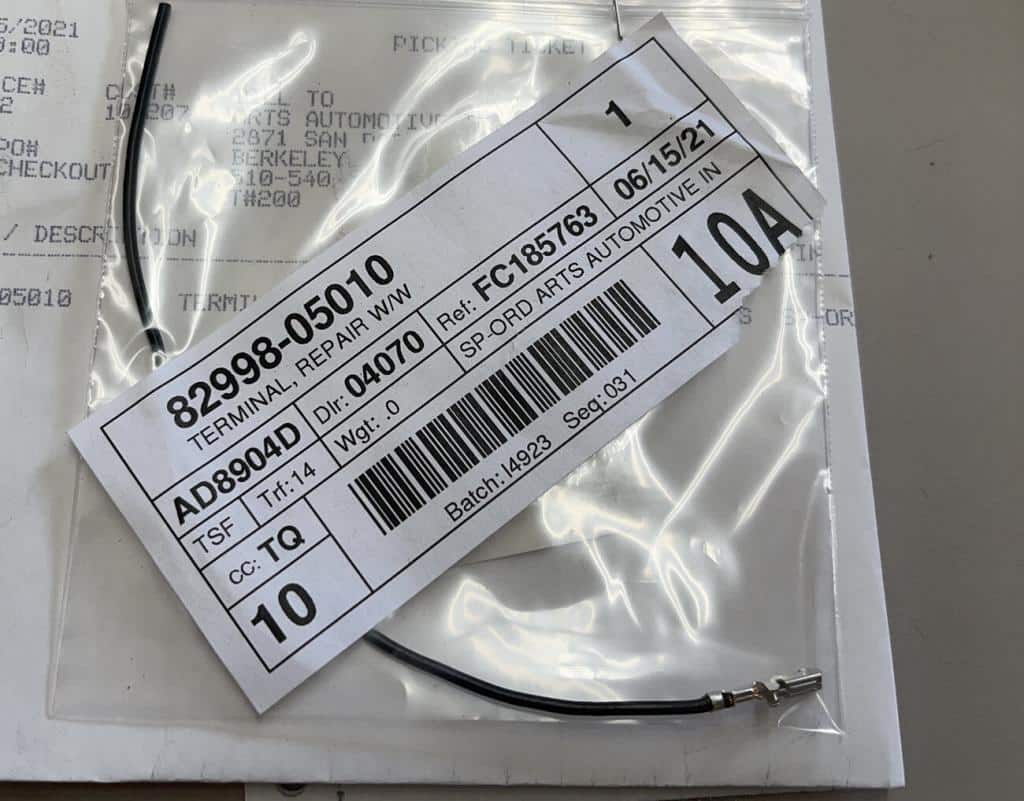

OBD2 repair terminal from Toyota

We got a call back a few hours later with a part number. If you’re trying to repair a Toyota OBDII connector, the correct part number may be 82998-05010. It’s the correct part for a Gen3 Prius at least and likely fits other Toyota vehicles as well.

Here’s the thing, this single terminal and pigtail is $20.92. Yikes! I mean it’s not really much money when it comes to an auto repair, but it’s way too high for what it cost to produce. I doubt Toyota is paying over .20 ¢ to have these made. I know. Warehousing, distribution, markup, etc. Even then, it’s still too much.

Connector Experts

There’s a company called Connector Experts, they have reproductions of OE connectors and terminals. They send us advertisements, but I’d never tried them. After some research, it looked like their terminal part number TERM86 would be the correct part, and it was. I couldn’t tell the difference between the OE terminal I’d purchased and the one from Connector Experts. The metal seems to have the same hardness and springy-ness, and all of the measurements were identical. No pigtail was included, but other than that, it looked like the same thing, only 10x cheaper.

Mouser also has a fair number of automotive connectors and terminals, but it’s a bit overwhelming trying to find the part you want.

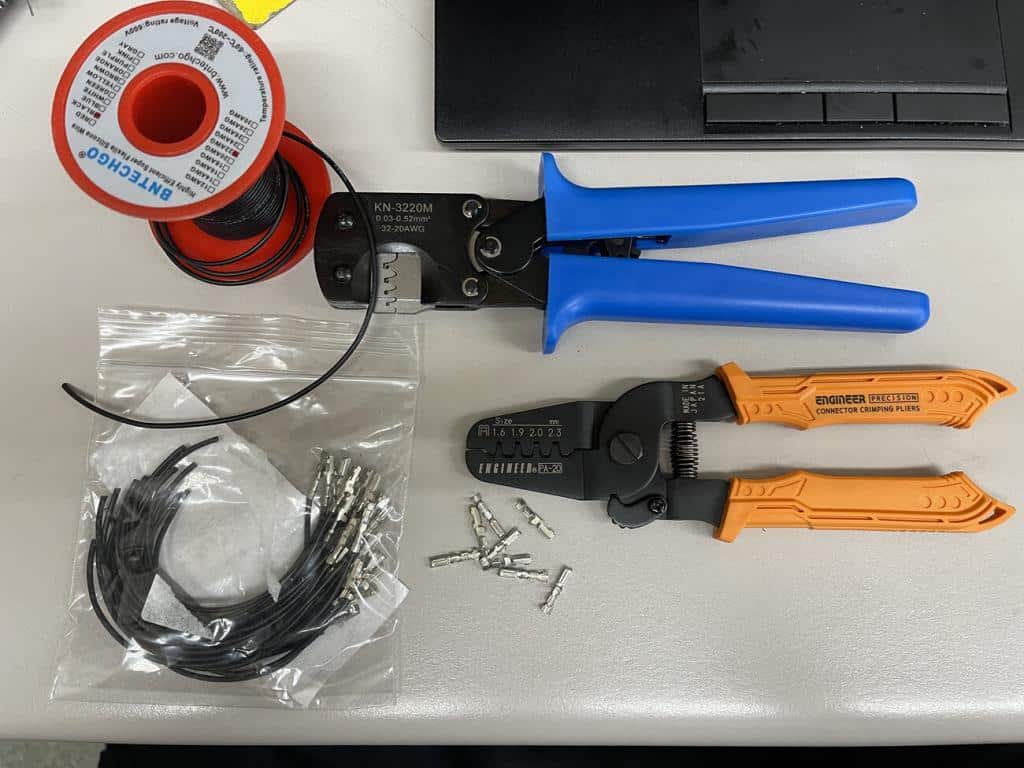

CRIMPING OBDII TERMINALS

All auto mechanics have at least one set of wire crimpers, but usually they’re geared toward old-school automotive terminal sizes. Usually 18 gauge wire is a small as they can go. I’ve been on a quest for a set of crimpers that will put perfect crimps in small open-barrel terminals and I’ve finally found a set. The orange crimper in the picture is made by a Japanese company called Engineer. They look sort of cheap, but they’re not. They’re very well made, and most importantly, they produce crimps that look exactly like factory.

Other articles you might like

If you like electronic repairs, you may also like these articles: