Art’s Automotive provides fast, accurate diagnosis and repair of all types of car electrical problems. We serve Berkeley and the nearby cities Oakland, Emeryville, El Cerrito, and Richmond. Not only are we experts in diagnosing intermittent electrical problems, but we also provide electrical connector repair, wiring harness repair, and high voltage testing for hybrids and EVs. And here’s something you won’t find at any other shop in Berkeley: we can diagnose and repair your electrical control units like ECMs, dashboard displays, combination meters, hybrid inverters, plug-in chargers, and key fobs. Of course we also do the same type of electrical repairs most repair shops do, like starters, alternators, batteries, and battery cables. If your car needs electrical diagnosis or repair, please give us a call.

Why Choose Art’s Automotive for Electrical Repairs?

SPECIALIZATION

We specialize. We work on only four makes of cars. What’s so great about that? For one, we’re familiar with the systems. The first thing a mechanic does before touching a single tool, is find out how the system is supposed to work. If you don’t know how it should work, you certainly can’t tell if it’s not working correctly.

Familiarity means more than just knowing how a system functions. It means we may already know how a particular sensor or actuator circuit works, because we’ve worked on the same one before. We may be able to save time on reading descriptions and diagrams.

Finally, we may have seen the same problem before. A quick verification of the what we think the problem is, and we save a huge amount of time. Why should you care how long it takes us to find the problem? Because you’re paying us by the hour!

EXPERIENCE with electrical car repairs

“They’re a bunch of gray hairs”. This might sound like an insult, but in the trades it’s not. Skill comes with experience. We’re not lifting engine blocks like we once did, but we sure do know a lot more than we did back in our “prime”. The best way to learn something, and remember it forever, is to screw up. We’ve been doing this so long, we might have already made every mistake there is, and as a result, we’ve figured out how to do diagnostic work quickly and efficiently without messing up.

There’s nothing wrong with learning. Everyone’s got to do it before they can move on to “knowing”. And as an industry, we really need fresh blood since the 18-25 demographic accounts for only 2% of the automotive technicians currently working. That said, would you rather pay someone hourly who’s at the top of their game, or someone who’s still figuring things out?

EQUIPMENT AND TOOLS

Electrical diagnosis and repair used to be a mostly analog game. Voltages between 0V and 14.5V that we’d measure with a voltmeter. High tech stuff back in the 80s. We’d use a fancy voltmeter with a swinging needle, not a cheap test light like those other guys.

Electrical car repair is seldom analog these days. Now everything’s digital. Zeros and ones, each represented by a number of different voltages, all depending on the what the engineers decide the the best bang for the buck this week. The primary tool for digital diagnosis is the factory scan tool. I mean you can look at the zeros and ones with an oscilloscope, but you really can’t say much more than they exist at the point where you’re measuring them. What are they saying? I don’t know. That’s what the scan tool is for.

Modern Scan Tools Are For More Than Just Powertrain

In case you’re thinking that a scan tool is just for powertrain diagnostic work, it’s not. Your horn, wipers, brake lights, climate control, windows — blah, blah, blah, you get the idea. Just about everything electrical is controlled by a node somewhere on the network. It’s called multiplexing and it saves weight and money on wires. Besides, the pure volume of electrical stuff on modern cars wouldn’t be possible without it.

Electrical car repairs are a whole lot easier with an OE scan tool. We have a factory scan tool for every make we repair. Trying to diagnose a car without one is possible, sometimes. However, diagnosis is billed by the hour and going to a shop with the right tools will save you money.

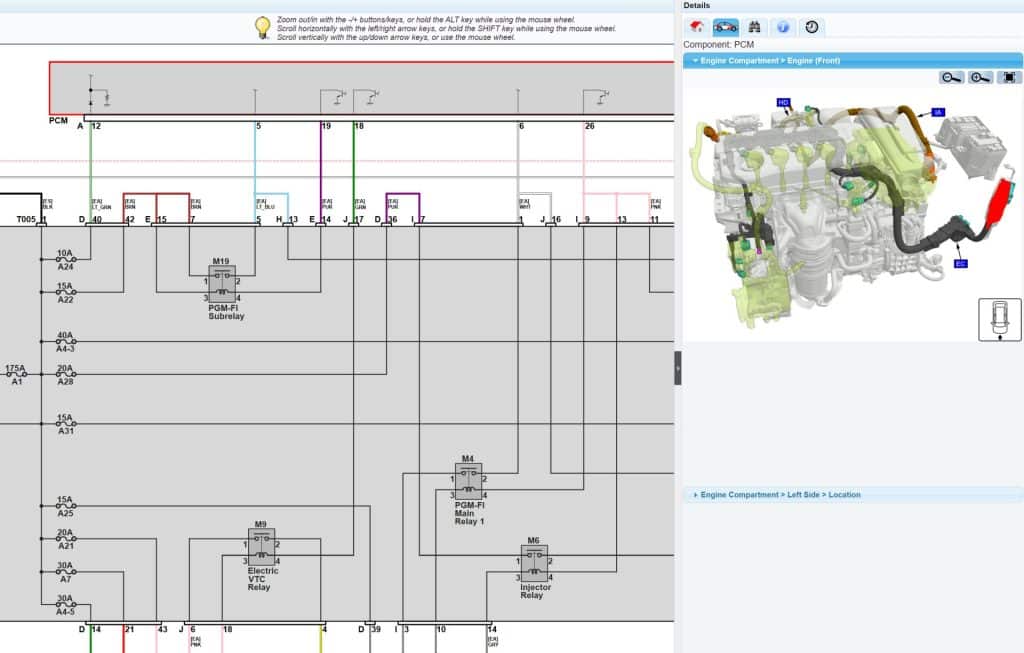

INFORMATION

In our view, using diagnostic and repair information directly from the vehicle’s manufacturer is necessary and well worth the expense. Using OE information services will save us time and you money.

Here’s the issue. Aftermarket information services, even those sourcing data from original manufacturers, frequently introduce errors through the “telephone game” effect, where restating or copying information leads to inaccuracies. Another issue is that aftermarket resources may incorrectly organize data or attribute it to the wrong vehicle, which can result in misdiagnosis and unnecessary part replacements.

Subscribing to original manufacturer information services helps us efficiently and accurately diagnose and repair electrical problems and avoid costly mistakes and wasted time.

Common Car Electrical Problems We Fix

- Battery and alternator issues

- Power windows, locks, and mirrors

- Dashboard warning lights

- Starter and ignition problems

- Hybrid and EV electrical diagnostics

In-House Electronics Repair in Berkeley

Many customers are surprised to find we can repair their automotive electronics rather than just installing new parts. As you may know, some automotive electronics are very expensive. If we can fix it and you don’t need to buy a new part, it’s a win win. You win because you may pay hundreds or even thousands less. We win because we can bill for our labor instead of getting a tiny markup on a part from a dealership.

What Electronics Can We Fix?

So, what electrical components can we fix? It depends. Some issues are well known to us, and we can quote an exact price up front. The Prius combination meter is a good example of that type of repair. Other times we’ve never seen a failure before and we don’t know what’s causing it. In those cases it’s 50/50, and sometimes less. To be clear, if you have a Toyota, Subaru, Honda, or Mazda we can always fix your problem. However, sometimes you’ll need to buy a new part.

It would be great if we could always fix every broken component, but that’s not the case. There is no manufacturer support for electronics repair. No service information. No diagrams. No parts availability. They sell parts and they’d like you to buy one. This means that sometimes we can’t figure it out, can’t source the needed part, or can’t program the needed part even if we find it. However, keep in mind that 99% of auto repair shops do no electronic repair at all, so their success rate is 0%. Your odds are way better with us.

How much do we charge for electronics repair?

What we charge for electrical component repair depends on a lot of factors. As mentioned, some jobs are a fixed price. Fixed price jobs are based on the time is takes to do the work, any overhead associated with the repair, as well as some of the cost of the time we originally put into diagnosing the issue. That’s one of the great things about specializing. There are pattern failures. If you invest time into solving an issue, and it turns out to be a common issue, you can recover the time invested plus additional profit and still do the job cheaper than any of the competition.

Unknown electronic problems

So, what if we don’t know what the problem is already? How much does it cost? Here’s some good news. Many times we’ll be willing to take on a challenge on a contingency basis. Now to be clear, this depends on you committing to a traditional repair.

What I mean by traditional repair is you pay for diagnosis, removal and replacement, and a new part, just like you would at any other shop. I will then attempt to diagnose and repair the failed component. I might spend 3 hours testing, trying to source electronic components, soldering, etc.

What if we can’t fix it?

If in the end I can’t fix it, I won’t bill you for my time or purchases. However, you will need to pay for the traditional repair.

I don’t know exactly how long I spent finding out how to repair the Prius onboard charger, but it was well over 8 hours over two separate attempts. No customers have been billed so far, but I’m hoping we’ll see another failed charger soon and I’ll be able to recoup some of my losses, and then start making a profit since I now know how they fail and how to fix them.

Repair attempt fee

Other times we may want to share some of the cost. A modest repair attempt fee whether we fix it or not, and a good profit if we are able to fix it.

It really depends on the situation. It makes sense to tackle a problem on a newer car where we’ll have an opportunity to recover our R&D work, but it doesn’t when looking at an older car where parts are no longer available and not many are still on the road.

Water Damage Repair

Another case where we’d want you to agree to a repair attempt fee would be a water damaged component. That’s not going to be a pattern problem first off, and secondly it’s impossible to predict success until you’re already there.

What typically happens with water damage is that vias (small passages from one side of the circuit board to the other) corrode away and break the circuit.

Water damaged vias can be repaired if the board is two sided, but sometimes there are more layers sandwiched between. I won’t know until I repair what I see, and that can take a long time. The risk is too high and there’s no chance of future profit doing the same repair. In this case you’d need to be willing to pay my costs, even if the board doesn’t end up fixed.

Whether this makes sense will depend on the cost and availability of the component. Used parts are also an excellent option in some cases. Regardless, we’ll let you know about all of your choices and you’ll be able to decide what you want to do.

Microsoldering

Electronics keep getting smaller, which makes repair more difficult, but for electrical device made, there are tools and techniques that make repair possible. We don’t get into re-balling BGAs (tiny pinless microchips), but we’re proficient and replacing and re-soldering most types micro controllers.

In repair manuals you’ll often find statements like, “The LEDs are integrated into the dash display and cannot be replaced. If one fails, replace the dash cluster”. These meters are often thousands of dollars and the LED can be replaced, if you can solder.

A little research to source a replacement LED and some soldering skill and we can repair units like this for a tiny fraction of the cost for replacement.

Downsides

Time is one potential downside. Let’s say you bring a car in for diagnosis and we find a faulty component. We think we may be able to fix it and give you our best guess at a repair price and a replacement price and you say go for it. It’s going to take some time to look at the part. If we determine we can’t fix it, it may be too late for that day’s order.

However, this can work out the other way at times. Lately we’ve had a lot of trouble getting electronic components. Backorders for weeks or months at times. We also sometimes fix an issue on the same day but would have need to wait a couple days for the part to arrive. Sometimes repair is a much faster option.

Good as new?

As far as reliability goes, I think that most of the time repairs are as good as new, and in some cases I’m able to improve on the area of failure. Buying a higher value capacitor or higher wattage MOSFET is no big deal since they’re so cheap. Car companies buy these in the millions, so a 25 cent price difference is a big deal to them. To me, especially after finding the component was underrated and failed, buying the best possible replacement makes a lot of sense.

Having said that, components do age, and we’re not replacing everything, so I supposed a different type of failure is more likely. However, all electronic designs usually have some weak point, and it’s common to see one fault over and over.

Finally, some components are so cheap that it’s not worth trying to fix them. Honda keys are a good example. It might just have a broken lock button but if Honda is selling a new key for $48, why bother.

Warranty

We’ll warranty our electronic component repairs just like all of our repairs. 1 year, unlimited mileage unless we say differently before the repair and on the paperwork. The warranty is limited to the cost of the original repair. For instance, if we repair your $2500 control unit for $350 and it fails 6 months later, and we’re unable to fix it the second time, we’re not buying you a new control unit, we’re giving you $350 back.

Local electronics repair only

We don’t do any mail order repairs at all. We mostly work on components for cars that are in for diagnosis and repair. Occasionally we’ll take a project for another shop or someone doing a DIY project, but mostly we repair whole cars.

Book Your Electrical Diagnosis Today

If you have an electronic problem with a Toyota, Subaru, Honda, or Mazda, give us a call. We’re always willing to talk about it and if it’s not a job for us, we may have some referrals to other good auto mechanics in the area.

FAQs

How long will the electrical diagnosis take?

Most of the time we’ll be able to diagnose your problem in a single day. Often we can even get the car repaired on the same day if the parts are available. However, this may not hold true for intermittent electrical problems. If an electrical problem is not acting up while we’re looking at it, you may need to be patient. Sometimes we can get intermittent problems to act up with wiggle and tap testing, or by heating or cooling a suspect component, but sometimes there’s nothing to be done except wait for the problem to occur.

Do you work on hybrids and EVs?

Absolutely! In fact it’s what we’re known for. If you’d like to read a little bit more about our hybrid and EV capabilities, click the link.

How can I tell if I have an electrical problem?

It can actually be difficult sometimes to determine if a problem is mechanical or electrical. For example, let’s say a heater blend door servo is setting a code because it’s not moving. It may not be moving because someone dropped a fork down the defroster vent and that’s now blocking the door, or it could be an issue with the wiring or the servo motor itself. The only way to find out is to spend a bit of time and figure out what’s going on.

I’ve been to several other shops and my car still isn’t fixed. Will you be able to diagnose my electrical issue?

Probably. We’re very good with automotive electrical repair and we have the best diagnostic equipment available. However, intermittent issues can make things difficult. If the problem occurs frequently, we should be able to find and fix it. On the other hand, if your car does something once every two months, that’s going to require a lot of patience.

How much will electrical diagnosis cost?

We bill by the hour for diagnosis, but most of the time we’ll get your problem figured out within an hour. If not, we’ll call to explain what we’ve checked and found, and give you our best guess at how much additional time we’ll need.

If I have the repair done at your shop, will the diagnosis be free?

No. We bill for diagnosis, but we stand behind it.

Do you repair or install aftermarket electrical car accessories?

Sorry, but no. If an aftermarket device like a car alarm is causing problems, we can remove it for you, but we won’t diagnose or repair the issue. For aftermarket car audio and alarm issues, we usually recommend Hi Tech Car Audio in El Cerrito.