Mechanics often recommend fuel additives to clean intake deposits, but they won’t help with all types of engines. Fuel additives won’t prevent or remove intake valve deposits on direct injection (DI) engines. In this article, we’ll explain why that is and how to remove intake valve buildup on DI engines with effective intake valve cleaning methods.

Port Injection vs. Direct Injection

In port injection engines, fuel additives can effectively clean the intake valves. This is because the fuel injector sprays fuel directly onto the intake valve, helping to wash away any deposits. Because of this, intake valve deposits are relatively uncommon in port injection engines due to this constant cleaning action. If deposits do form, adding fuel additives during fill-up can help remove them.

However, in direct injection engines, the fuel injectors are located directly in the combustion chamber. This prevents fuel from the injector from washing the intake valves.. As a result, DI engines are prone to carbon buildup on intake valves, and fuel additives won’t help. This is where specialized direct injection engine maintenance becomes essential.

The Role of Oil Maintenance

Crankcase Ventilation

Oil maintenance is crucial in managing intake valve deposits, especially in DI engines. Engine condition and the leakage of combustion gases past the piston rings (called blow-by) significantly impact this process. These gases enter the crankcase and need removal to prevent oil contamination, pressure buildup, and potential explosion hazards.

In the past, vehicles had a tube (called a draft tube) that released engine vapors directly into the air, contributing to the black lines seen on freeways in old photos from the 1950s to the 1970s. However, modern vehicles route these vapors back into the engine through the intake system. These vapors are laden with nasty, sticky substances that contribute to the formation of deposits on intake valves when they re-enter the engine.

Oil Quality and Change Interval

If you use poor quality oil or don’t change your oil frequently enough, several problems can occur. First, as the oil ages, it oxidizes, creating sticky sludge and varnish. This sludge can flow across the intake valves, creating deposits. Another issue is oil dilution. Blow-by past the piston rings contaminates the oil with fuel, especially in direct injection (DI) engines. The fuel thins the oil, leading to additional blow-by and further deposits on the intake valves. Third, acids form as the oil degrades, etching surfaces and allowing deposits to stick more easily, particularly on the piston rings. Finally, motor oils contain additive packages that help clean the inside of the engine. Over time, these additives deplete, making the oil less effective at cleaning. Regular oil changes and using high-quality oil can help prevent these issues.

Why Are Intake Valve Deposits a Problem?

What symptoms would you expect when the intake valves are dirty? We usually see cars come in with complaints of rough idle or low engine power. Sometimes carbon on the valve stem can cause the valve to stick open and cause popping through the intake after a cold start up until the valve comes loose.

Cleaning intake valves is one of the more satisfying repairs. There’s quite a difference between the “before” and “after.”

Internal combustion engines are like an air pump. The more air the engine can “pump,” the more power the engine has. A partially clogged inlet to the combustion chamber reduces the air flow and volume. Intake deposits block the flow of air and reduce the engine’s power and efficiency.

Deposits form slowly, and like a frog being boiled, drivers often don’t notice the decrease in engine power until it becomes severe. However, once the power is restored in a single day after an intake valve cleaning, there’s a very noticeable difference, leading to happy calls from customers post-repair (our favorite kind).

How to Remove Intake Valve Deposits on a Direct Injection Engine

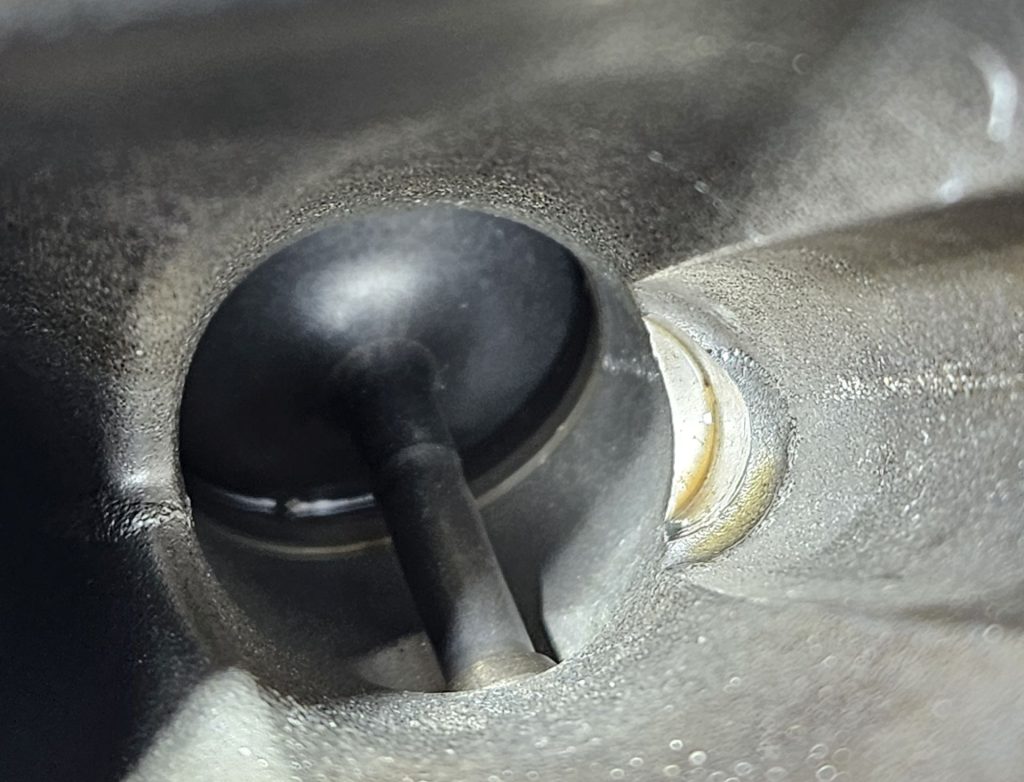

The most reliable way to remove intake valve deposits on a direct injection engine is to remove the intake manifold and use a walnut shell blaster to remove the deposits. This walnut shell blasting method uses crushed walnut shells blasted with compressed air to clean the valves.

The walnut shells are much softer than metal and will not damage the engine if an errant particle makes its way into the combustion chamber. The procedure is simple: turn the engine by hand until the intake valve is fully closed, then use the walnut shell blaster to clean the carbon deposits. This makes a colossal mess, so most blasters include an adapter to cover the intake port and a vacuum to collect the walnut shells.

Some shops use a method called ‘fogging,’ which involves spraying a mist of cleaning chemicals into the intake while the engine is running. It’s a relatively quick and easy process, but there are two issues. First, there’s the risk of severe engine damage from hydrolocking, where the engine is flooded with liquid. The other issue is that it doesn’t work. In our experience, it doesn’t make any measurable difference, even when repeated several times.

What Vehicles Get Carbon Buildup?

Any vehicle with direct injection can develop intake valve deposits, but so far we’re only seeing issues with a few models. Since we’re a Japanese specialty shop, we’re a little late to the game. Many European brands have had direct injection for years, whereas we started seeing DI appear on Japanese cars around 2015. So far the most common issues have been with the Honda Fit with the 1.5L L15B1 and the Subaru WRX, Forester, and Legacy with the FA20F engine. However, as the many models with direct injection age, we’re expecting to see many other models added to this list.

Conclusion

For DI engines, fuel additives won’t help maintain clean intake valves. Effective oil maintenance is the best preventive measure you can take. This means both the quality and frequency of your oil changes matter. If your DI engine is worn (because it didn’t get effective oil maintenance), you’ll likely need cleaning more often due to increased blow-by. The only real solution to intake valve deposits is walnut shell blasting, which can be a little pricey but will be worth it.

Do you live near Berkeley and own a Japanese car? Do you have performance issues that might be fixed by walnut shell intake valve cleaning? Please call us at 510-540-7093 to set up an appointment.