Sometimes I secretly wish we were a little more like Cuba. No, I’m not communist, and I love this country despite its faults, but Cuba does have something that we don’t. What? Ample opportunity to repair things using skill and creativity. We can’t fix anything here. I mean we can, but nobody in their right mind would pay to fix something that can be replaced for less. When a part breaks, a mass produced replacement is nearly always cheaper than the repair, at least when you’re paying American wages.

This is the story of one of those rare times when the value of the part is so much higher than the cost to fix it, I actually got to fix something.

What’s that weird sound my Prius is making?

This Prius came in with a noise complaint. There was a strange whirring which we traced to the inverter coolant pump. The pump wasn’t bad, but there was no coolant in the system so it had cause to complain. We found this nipple had been knocked out of the transmission case. How that happened remains a mystery, but here it was. The nipple was bent and just flopped around when inserted into the case. There was no saving the nipple.

The part can’t be purchased separately

The bore in the transmission looked fine. The nipple was very thin metal so it didn’t crack the case when it came out, which is great. We called Toyota to order a new nipple. No luck. The nipple is part of the transmission case and isn’t sold separately. We thought about pulling one from a junk transmission, but the the part is pressed into place and the metal is very thin. Chances of removing the nipple without damage were pretty slim.

Design and build a new part

Since a transmission is about $6000 (pretty close to the value of the car), there’s room to get creative and make a new part. There are no doubt people who could make this part a lot faster and better than I could. I’m a professional mechanic and hybrid expert, not a professional machinist. However, manual machining is one of the things I love doing. I own 20″ mill, a 8×12 lathe, a TIG welder, and various other tooling. I spend a lot of my free time making things.

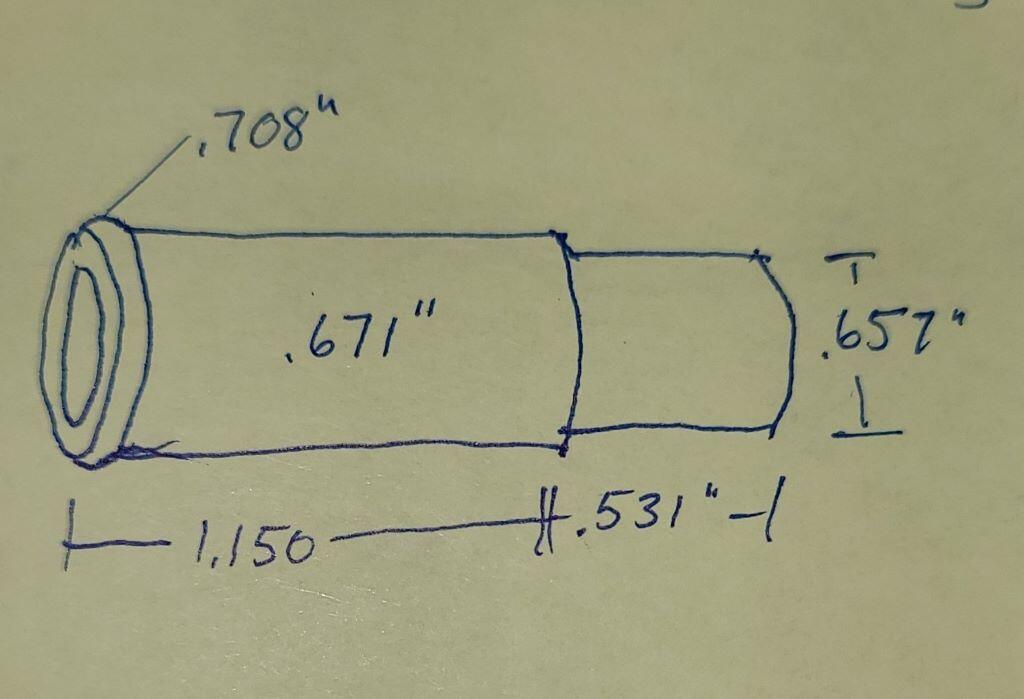

After measuring the bore in the transmission case with a snap gauge and the damaged nipple with a set of calipers, I came up with this plan. I don’t want this rusting so 304 stainless seems like a good material to use.

You may notice that there’s no inner dimension on my drawing. Flow restriction isn’t a concern since the Prius inverter pump barely moves any coolant. Machining a very thin walled part is a concern though since it would require more setup to machine without crushing. I decided to go with a 3/4″ seamless 304 tube with a 0.120″ wall thickness.

304 Stainless for a lasting repair

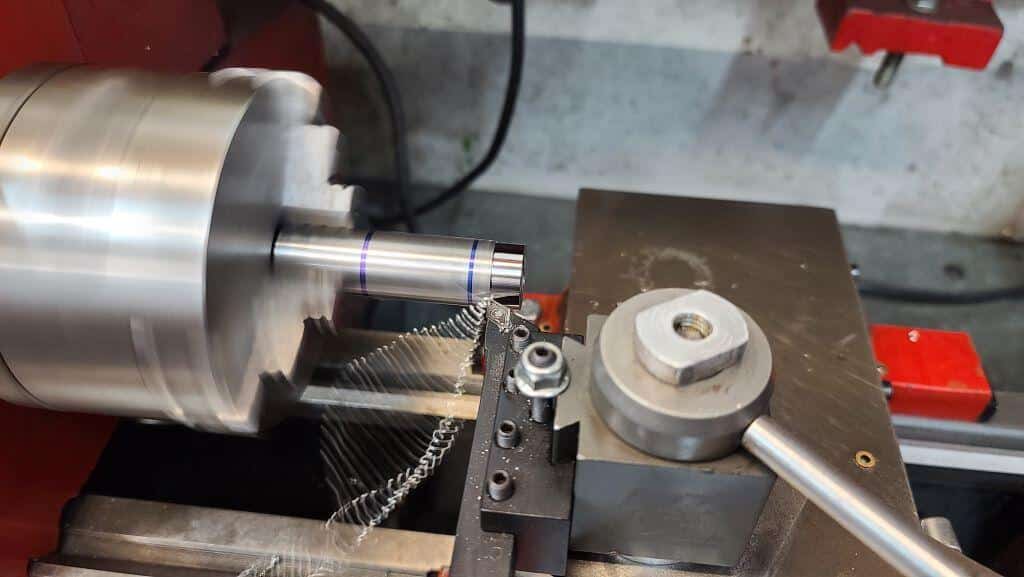

McMaster delivered the tube next day. I hadn’t machined 304 on my small lathe before. I usually machine 6061 aluminum and 12L14, 1018, or drill rod depending on what I’m doing. Luckily my machine did OK, even with the excessive stick-out you see in the picture. I corrected this poor setup once I started taking bigger cuts. Concentricity is completely irrelevant for this part, and the through hole in my chuck can handle 3/4″, so the better plan was to feed the stock out, re-chucking it each time I completed a section. A word of warning for anyone machining 304: the chips are insanely sharp and dig into your hands like a fish hook. Ouch!

A perfect fit

I discovered a while back that it’s a poor machinist that blames his tools. It’s absolutely possible to make very precise parts using low end tools. I purchased my 8×12 lathe around 15 years ago for about $500. I spent years wishing I had spent more and bought a better lathe because I couldn’t hit my dimensions reliably. It wasn’t the tool. It was me. Buying a machine doesn’t make you a good machinist. Lots of reading, YouTube, and practice makes you a good machinist. This part is 2/10,000 of an inch off what I put in the drawing.

I’m not an engineer, but I can look stuff up

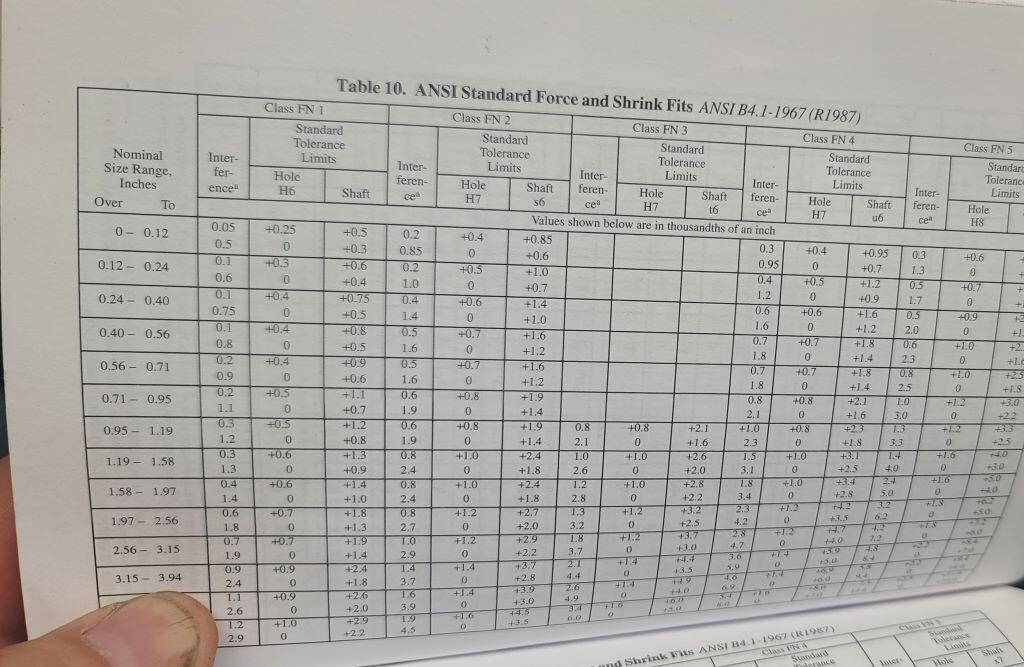

I was aiming for the lighter side of class FN 2 press fit. For a shaft/hole between 0.560″ and 0.710″, the shaft should be about 0.0005″ to 0.0016″ larger than the hole. I didn’t want to have a very tight fit because there’s no way to use a press. I need to tap the tube into the transmission with a hammer. Here I ended up with a shaft that was 0.0007″ larger than the bore, which I was happy with. As a backup, I used Loctite 648, so even if the fit wasn’t sufficient, the nipple wasn’t going anywhere.

Ooh! Shiny!

This is my favorite part — when the project is complete and I have a shiny bit of metal that will fit perfectly (or so I hope). The original nipple was very thin and the barb was rolled. There’s no way this could be rolled, even if I had a tool to do it, so I just machined the barb into the part with a 60 degree cutter and smoothed it with a file and sand paper. It’s not strictly necessary, but it adds a level of safety and might prevent the hose from being blown off if the system is over-pressurized.

A permanent repair

Three solid taps with a heavy hammer were enough to drive the nipple into the transmission case. The beads of condensation are on the nipple because it’s cold. I put it in the freezer for several hours before installing. I also warmed the transmission case with a heat gun for about 10 minutes. The nipple shrank due to the cold and the bore in the case expanded because it was warm. The ring of green at the joint is Loctite 648. This nipple isn’t coming out without a fight.

Success!

After refilling the inverter cooling system and pressure testing, it looks like this repair was a success! The loud pump even quieted down. I think I’ll make myself a Mojito tonight. Until then, back to opening boxes and bolting on parts. sigh

Did you enjoy this article? Here are some similar articles you may like.

Repairing a captive nut in a sub-frame