The most common cause of a Honda heater fan not working is a failed blower transistor. This article will cover how to diagnose and fix problems with Honda blower motor circuit.

The blower motor is the fan that produces airflow for the heater and air conditioner, but you probably already knew that since you’re reading this. Let’s get started.

A little Honda heater fan history – The blower resistor

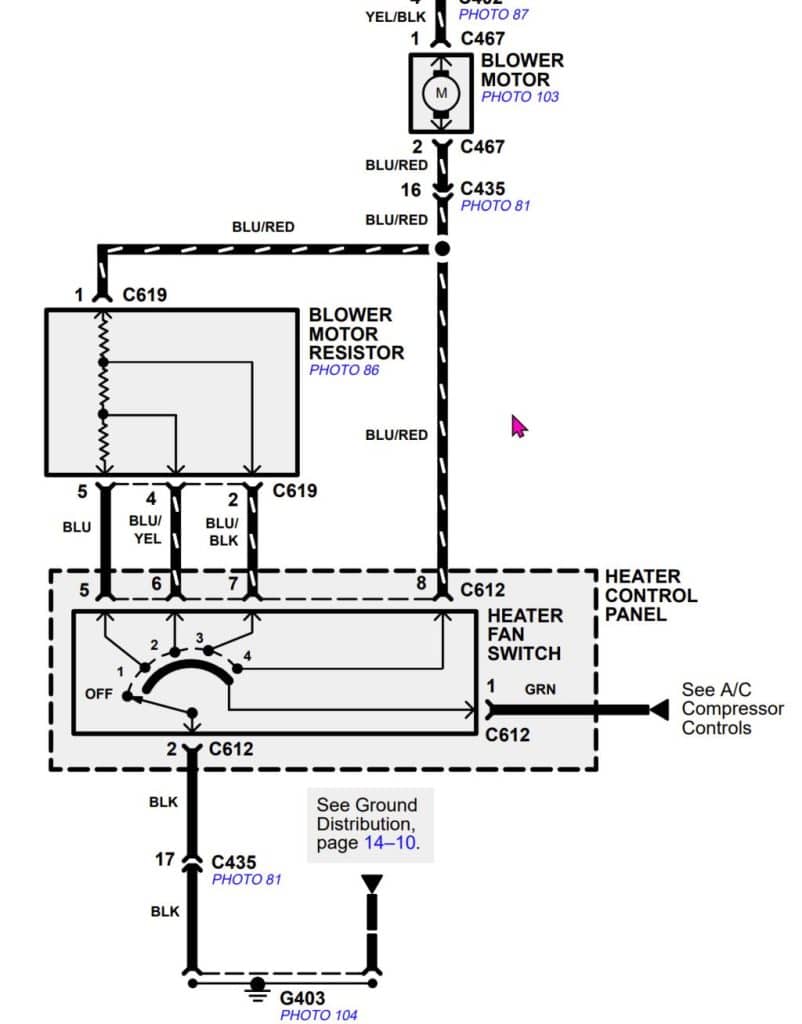

A blower transistor is a replacement for Honda’s earlier blower resistor. Both components have the same function – regulating the fan speed and thus air flow from HVAC vents. The early blower resistor was actually several resistors in a package.

When the driver selects a low fan speed, the current flows through the fan motor and a high-value resistor in a series circuit. Since the resistor value is high, the motor receives less voltage and spins slower.

For each progressively faster speed, the current is routed through a smaller value resistor and the blower spins faster.

When the driver selects high, the blower motor is connected directly to ground through a shunt in the blower resistor and the motor receives full voltage.

You can diagnose a failed blower motor resistor very easily. If the blower doesn’t work in one or more lower speeds, but works fine in high, you likely have a bad blower motor resistor.

My car isn’t 30 years old. Why is my Honda heater fan not working?

Modern cars don’t use a blower resistor. Honda replaced the blower resistor with the blower transistor in the 2000s. Why’d I waste your time with the history lesson? Well, the new Honda heater fan control does the same thing but in a different way.

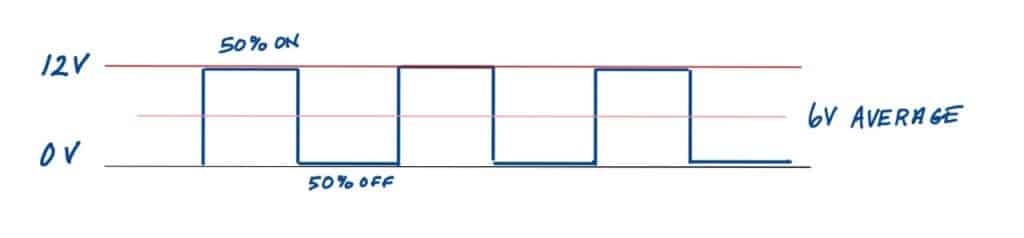

Honda still uses a brushed DC motor and still controls the motor speed by reducing the voltage available to the blower motor. The difference is that the fan motor voltage is reduced with duty cycle instead of resistance.

Honda controls blower motor speed with pulse width modulation

If the blower is turned on 1/2 the time and off 1/2 the time it will spin around 1/2 as fast as it would if it were on all the time.

Want it to go slower? Increase the off time and decrease the on time. Want is to go faster? Do the opposite.

How does a blower motor transistor work?

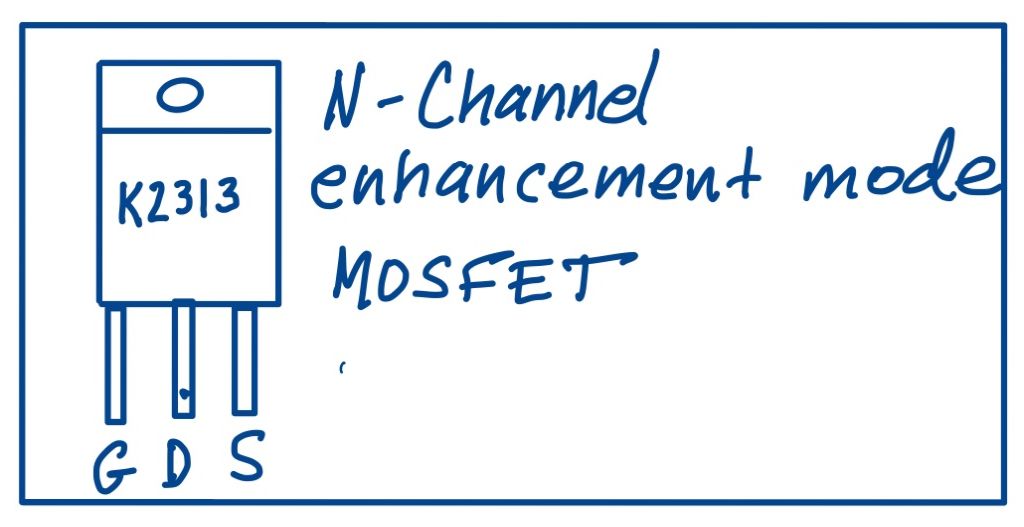

The blower power transistor is actually a very simple device. It’s a MOSFET (which is a type of transistor), a heat sink (to cool the MOSFET), a thermal cutoff (to protect the MOSFET from overheating), and a capacitor (to smooth the output a bit).

A transistor is like a relay. A small current can be used to switch a high current. Since Honda blowers are a relatively high current device, a MOSFET is a perfect driver.

A MOSFET has 3 terminals. Gate, Drain, and Source. The drain is connected to the blower motor. The source is connected to chassis ground.

When a positive voltage is applied to the gate, the drain and source are connected and the blower motor runs.

The HVAC control unit pulses duty cycle power to the gate. The ratio of on time to off time controls the blower motor speed. 100% on time = full speed. 0% on time = off.

A blower resistor had 3 speeds plus high. In contrast, blower transistor can create infinite speeds between off and max.

What causes the honda blower problem

Honda didn’t intend for people to fix their own blower motor power transistors. However, the electrical engineers must not have got the memo because they put effort into making it repairable.

For one, compared to most automotive electronics the blower motor transistor is easily disassembled and soldered. A pocket screwdriver and soldering iron is all that’s needed.

Another more telling sign is the inclusion of a thermal cutoff. What is a thermal cutoff? Well, it like a fuse but instead of blowing when excessive current flows, it blows when it gets hot.

To the right is a N109 thermal cutout made by Panasonic, part number EYP-2BN109. At 114 degrees C, it will blow. Once it has it cannot be reset, just like a fuse.

How do you test it? Just like a fuse. Use an ohmmeter to check continuity. If it’s open, it’s bad.

So, if Honda doesn’t sell this part, why was it designed in? Its only purpose is to protect the MOSFET. If this isn’t a serviceable part, why include it?

A brief aside

After this article was published one of our customers pointed out that the part has been discontinued, but that NTE8115 should be a suitable replacement. It opens at 117C.

Another note from our customer. Another possible purpose of the thermal cutoff may be safety.

He suggested that it might be possible for the MOSFET to fail in an ON state then overheat and present a fire hazard and perhaps this is a safety device. He’s in the electronics industry and knows more about this sort of thing than I do.

When I tried to come up with some evidence to support this theory, I started with Wikipedia. The first sentence of the thermal cutoff article starts with, “A thermal cutoff is an electrical safety device…”.

But I also found some evidence the TCOs are used to protect MOSFETs in this Stack Exchange post, and the method suggested matches the setup I found in the Honda blower transistor.

The truth is I don’t know what the intended purpose is. If you decide to believe some guy on the internet (me), and choose to bypass your TCO with a wire as I suggest below, be warned. I will employ the Tucker Carlson defense if you sue me. Nobody should take me seriously 😉

On with the article.

HOW TO FIX A HONDA BLOWER TRANSISTOR

If you own a Honda, and your blower motor isn’t working, be happy the engineers couldn’t bring themselves to design a crappy part. You can buy a new thermal cutoff or simply replace it with a wire. Of course, if you go the wire route, your MOSFET protection is gone and next time you’ll need to replace it, but that’s not the end of the world. A replacement MOSFET is about $15.

Why would you want to fix your Honda blower transistor?

This is a simple answer, money. Honda is charging about $150 for these blower power transistors. If you’ve got some DIY skills and time, why not do your own Honda blower repair.

Consider why it failed though! A clogged cabin filter or failing blower motor may be the root cause. High current draw will kill this device.