The title does a pretty good job of describing the purpose of this article: this is a primer on the process involved with major engine repairs and other projects that begin with a “tear-down” estimate. It is primarily intended for our customers, but should be useful for anyone working with an honest shop in California.

I’ll start with the example of an engine repair, but most of the main points apply to any major repair.

Replace With New vs. Dissassmble and Repair vs. Install Used

There are three ways to address mechanical engine problems:

- Replace the engine, cylinder head, or block with a re-manufactured or new component

- Disassemble the engine and repair or recondition components that are worn out

- Install a used engine or component

Each of these approaches has its advantages.

- The advantage of purchasing a head, block, or whole engine is an increased chance of the initial estimate covering the entire repair. This makes the cost predictable, but more expensive.

- The advantage of repairing is that the cost will almost always be lower, but less predictable. There is no way to accurately estimate the total cost until the engine has been disassembled and inspected, and, if the damage is severe, it may end up costing just as much as a re-manufactured exchange.

- The advantage of a used engine is it’s low cost. The downside is that it’s a huge gamble; the used engine may or may not work acceptably. Therefore, Art’s Automotive almost never offers used engine, but there are many other shops that do.

Why Initial Estimates Often Change (“Tear-down Estimates”)

This article will give you an idea what to expect when working with a shop performing a major engine repair or overhaul.

Before you agree to start an engine repair, it’s very important to understand that the initial estimate will almost certainly go up. The initial estimate is a “tear-down” estimate. It includes all of the labor and parts necessary to take the engine apart, evaluate its condition, and reassemble it, but not necessarily to FIX it.. No mechanic can give an exact estimate for internal engine repairs, because none of us have x-ray vision.

At Art’s Automotive, we try to go beyond the basic tear-down estimate and we include operations and components that will likely be needed based on our past experience with similar jobs. We do our best to create a realistic estimate and this can make our estimates appear higher than our competitors if you don’t break it down and compare apples to apples. However, even when we do our best to guess what will be wrong with the engine, it’s pretty unusual that we will be able to imagine everything your engine needs completely accurately.

The Importance of Clear Communication

Before we begin a major engine repair, we explain all of this to our customers, but sometimes it doesn’t “sink in”. The shock of finding out out your car needs an expensive repair, coupled with the flood of technical jargon, may cause an information overload and details to start rolling out of your ears. If we begin a major engine repair with different expectations, it’s bad for everyone involved.

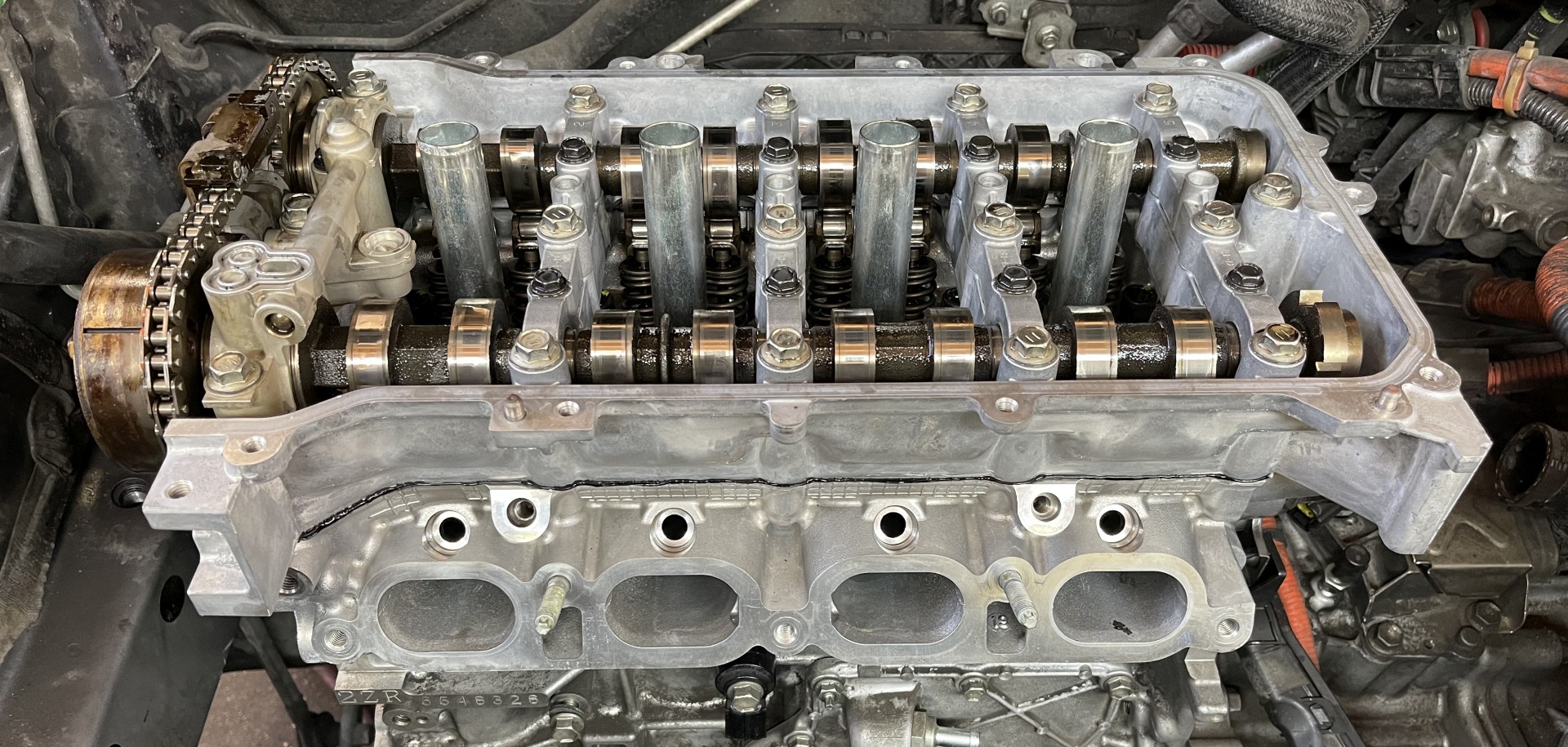

Here’s a scenario that illustrates how it can go wrong. Let’s say we diagnose a dead misfire caused by a burnt exhaust valve. We create an estimate to remove the cylinder head, grind the seats, grind the intake valves, and replace the exhaust valves because that’s typically what’s needed based on our past experience. We quote $2000 for the tear-down. After dis-assembly we find that the exhaust valve guides are worn oversize the one valve seat is so damaged that it needs to be replaced. We also find that the timing belt has not been replaced and is overdue. The additional work adds another $1000, bringing the estimate to $3000. Now, if the customer only “heard” $2000, he might be upset.

The Problems Caused by Delaying or Cutting Corners

What happens next is usually this:

The customer needs time to think. He might be upset because he feels tricked, like he was baited & switched. Or he might have had a tipping-point price in mind: a maximum price the car is worth to him. I truly believe that people sometimes hear what they want to hear, or they lock onto the first price they hear and start to start to work out how they can bend their finances around it.

How Delays Affect Both the Customer and the Shop

When a customer stalls a project we’re not happy about it. We expected and disclosed the price would go up based on what we found after disassembly. We made space on the schedule so the mechanic had time to work on the car and now we need to scramble to let in additional same-day work. The car is tying up valuable rack space. The mechanic looses time bagging, boxing and organizing parts for storage. Starting and stopping costs us money.

Risks of Cutting Corners to Lower Costs

If the customer doesn’t have and can’t get the money for the full repair, they ask about cutting corners to lower the cost of the repair. In the example above, we might skip the timing belt because it is preventative maintenance and is not broken. It would have been much less expensive to do it at the same time as the engine work, but it’s not required to fix the original problem. We might also skip replacing 7 of the valve guides because we are pretty sure that the engine repair will last well beyond the 1 year warranty if they are not replaced. Now the price is $2200 and is affordable.

Short-Term Savings vs. Long-Term Costs

However, cutting corners is bad for the customer and bad for the shop. Bad for the customer because the timing belt still needs to be replaced before it breaks and ruins all of the valve work, and the loose valve guides will result in less life before more engine repair is needed. The long term expense to maintain the car will be higher.

Risks of Future Engine Failure and Increased Maintenance Expenses

Bad for the shop because we’ve now signed our name on a sub-standard repair. Even if the repair fails beyond the warranty period, it’s still uncomfortable to when a customer comes in needing the same job done again. People don’t remember conversations from years before, which is why we write stuff down on the repair order, but even when it’s in black and white, it doesn’t really help the situation.

Making a Smart Decision About Major Repairs

So, what should you take away from this?

Don’t feel pressured to make a decision as soon as you get the news. Take some time to think about your options. Think of all the “what if” questions you can and ask your service adviser, that’s what they’re there for. Leaving your car for a few days while you think is not a problem. If you need a few paychecks to build funds, it’s best you tow the car out to avoid storage fees, but if you need a few days, we won’t charge storage and it’s not much of an inconvenience for us. Most importantly, don’t authorize repairs unless you’re sure you want to do the job and you know how much it might end up costing.

Trust Your Mechanic (or Find a New One)

If you’re not really sure that you believe your mechanic….. actually, let me stop here for a moment. If you don’t trust your mechanic, find a new one. Sometimes people’s impressions of other people are accurate. If you’re getting a sleazy vibe from your mechanic, don’t embark on a major project with him. You’re probably not expert enough to evaluate the validity of his recommendations, just like I can’t really know if my doctor is making the right calls. All you have is your impressions; there won’t be time to become an expert during the course of the project.

Verifying Repairs: Requesting Your Old Parts

If you want proof that additional work was actually needed and was done, ask for all of your old parts. You can’t inspect parts buried deep in the engine to see if they’ve been replaced, but at least you’ll be able to see the parts have been removed. In California, this is your right, as long as you ask before the job begins.

We won’t take offense if you ask for you old parts back. Many people are just curious about what’s being done to their car. Honestly, we prefer it when our customers make an effort to learn what we’re doing to their car. We’re proud of the work we do and we can’t show it off when no one is looking.

That’s all I can think of for now. Good luck with your project!