Tire balancing and/or wheel alignment may not solve all of your vibration or drifting problems. Have you ever had your car aligned, but it still pulls or drifts afterward? Or had a wheel balance, but the car continues to vibrate on the freeway? Yet your mechanic, maybe us, rechecks the alignment or balance and says it’s fine? Well, you’re probably not crazy, and your mechanic is not necessarily incompetent: you may have had a run in with the up-until-now, un-measurable lateral and radial tire forces.

If you’re in Berkeley, Oakland, Emeryville, Albany, El Cerrito, or anywhere in the East Bay, we may be able to solve your freeway vibration or pull once and for all. If you’re interested in how we’ll do it, read on.

REPAIRING PERSISTENT PULLS, DRIFTS, SHIMMIES & VIBRATION

Tire balancing and/or wheel alignment may not solve all of your vibration or drifting problems. Have you ever had your car aligned, but it still pulls or drifts afterward? Or had a wheel balance, but the car continues to vibrate on the freeway? Yet your mechanic, maybe us, rechecks the alignment or balance and says it’s fine? Well, you’re probably not crazy, and your mechanic is not necessarily incompetent: you may have had a run in with the up-until-now, un-measurable lateral and radial tire forces.

If you’re in Berkeley, Oakland, Emeryville, Albany, El Cerrito, or anywhere in the East Bay, we may be able to solve your freeway vibration or pull once and for all. If you’re interested in how we’ll do it, read on.

RADIAL FORCE

Radial force, which is more accurately called “Road Force Variation” (RFV), cannot be corrected by balancing a tire. As our Hunter rep puts it, “You can balance a football, but it won’t roll down the road smoothly!”. While it may seem like a football shaped tire would be easy enough to spot with a quick visual spin check, there are many tires with serious variations in road force that are visually undetectable. I’ll explain why a little later in this article.

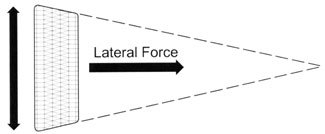

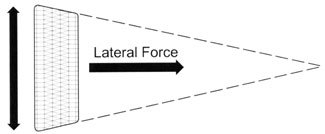

LATERAL FORCE

Lateral force is the amount of left or right pull generated by the tire as it rolls. This is usually caused by conicity, or in other words, being cone shaped. If you imagine rolling a cone on a flat surface, you can imagine that the cone will not roll straight ahead, it will roll in an arc towards the side with the small end. A tire where one side has a smaller diameter than the other will roll in the direction of the smaller diameter. If the tires are aligned perfectly (to produce zero pull) and a tire or tires are pushing the car to one side, the car will not go straight down the road. It may seem like conicity would be noticeable by looking at the tire, but it usually is not. I’ll also explain why this is a little later in the article.

Why your car might vibrate on the freeway, even after a wheel balance

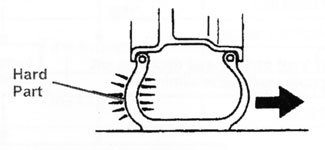

All tires have some variation in sidewall stiffness. The picture on the right illustrates this with imaginary springs on the sidewall. The red spring is stiffer that the yellow springs, so when the red spring is between the rim and the road, the wheel is pushed up, away from the road. This would cause a vibration while driving but is currently undetectable with any balancer other than the Hunter GSP9700. The GSP9700 measures the road force variation and takes it into account when balancing the tire.

Classifying lumpy tires

Sometimes there is more than one stiff point in a wheel assembly. The number stiff points on a wheel is referred to as the harmonic order. A wheel with one stiff point is said to have a “radial first harmonic” or R1H.

A wheel with two stiff points (as in the earlier football example) would be R2H.

A triangle shaped wheel would be R3H. The tire sidewall stiffness and the rim shape both contribute to the harmonic order. First order harmonics can be minimized by repositioning the tire on the rim. Second & third harmonics are more difficult to correct without rim or tire replacement, but at least they can now be detected.

It doesn’t take much out-of-round to cause a vibration

Only .030″ (the thickness of 2 of our business cards) of loaded runout can cause the same amount of vibration as 1.5 oz of wheel imbalance at 50 MPH. Any imbalance over 0.3 oz is considered excessive and might cause a perceptible vibration. This means a wheel with only .030″ loaded runout that had been balanced perfectly on a conventional balancer, could feel like it’s 5 times over the maximum allowable imbalance when you drive on it. Yet a wheel with .030″ of loaded runout might have no runout when it isn’t loaded; the imaginary springs may all be the same height, but still have different resistance to compression.

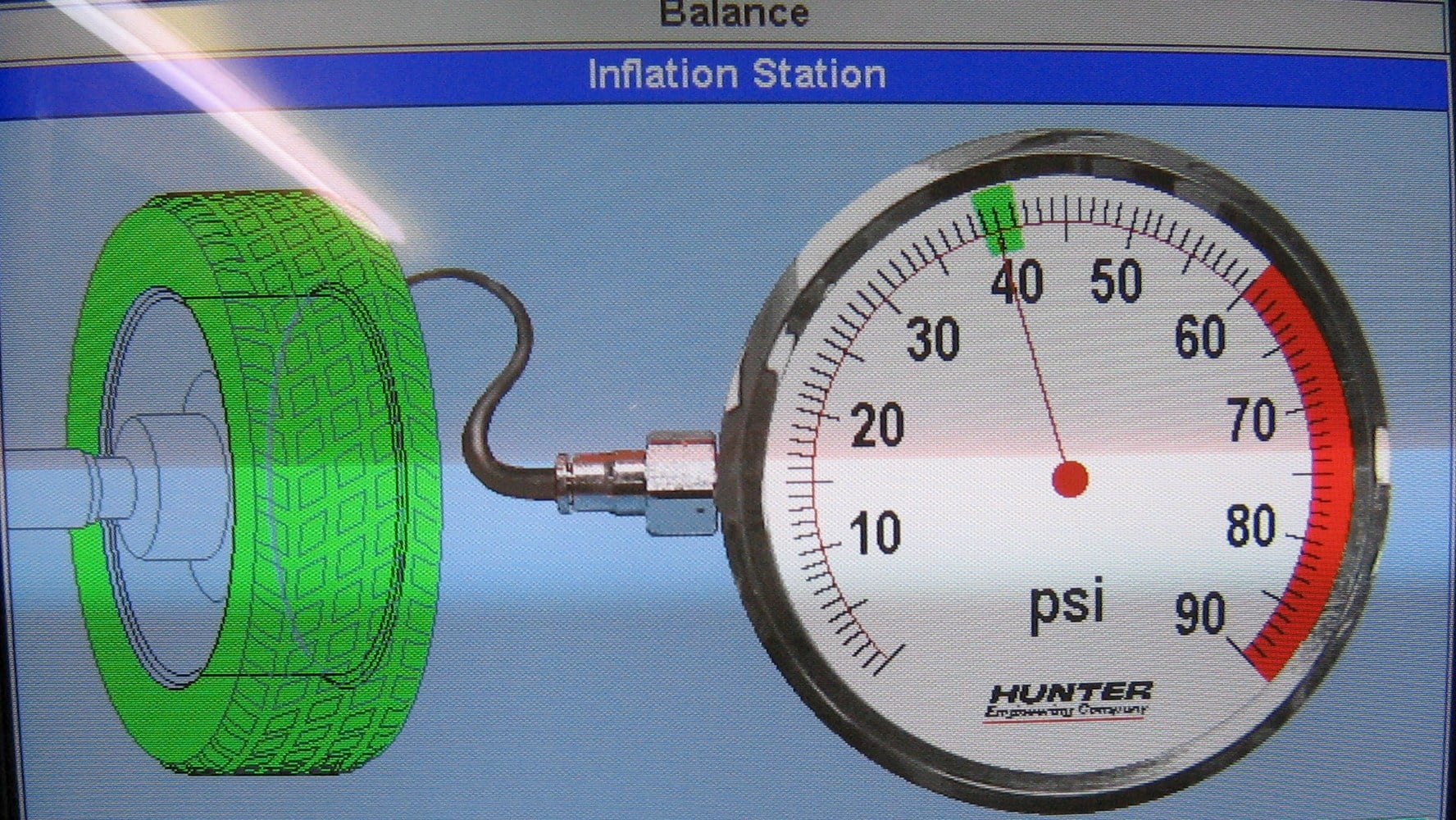

LOW TIRE PRESSURE INCREASES RFV AND TIRE PULL

Proper tire pressure is critical when measuring road force variations or lateral force. Road force variations and lateral force are both negatively affected when the tire is under-inflated A perfectly good tire could appear to be bad due to low tire pressure, so setting the tire pressure to the manufacturers specs is always the first step when doing RFV and LF measurements. However, tire pressure’s effect on road force variations and concentricity does not end once the tire has left the balancer; low tire pressure can cause tire pull, vibrations and wobbles as well. So, no matter how well your tires are matched to the rims and balanced, it’s up to you to maintain proper tire pressure once the car has left the shop.

No tire is perfect

Some variation in sidewall stiffness is normal for all tires. Even very expensive, name brand, high end tires will not be perfect. A $2000 set of top-of-the-line Michelin tires will not necessarily have a lower amount of RFV and LF than a set of Yokohama tires costing half as much. However, buying the cheapest set of no-name tires you can find does seem to increase your chances of getting a tire or tires with high RFV and LF.

WHAT DO THE RED DOT AND YELLOW DOTS ON THE SIDEWALL MEAN? WHAT DO THEY HAVE TO DO WITH TIRE BALANCE?

Tires are tested at the manufacturing plant for road force variation, conicity, plysteer, and balance. The heaviest point of the tire is marked with a yellow circle, and the stiffest point of the tire is marked with a red dot. It’s common practice match the red dot with the low point of the rim if the location is known. Some rim manufacturers mark the low point in the rim with a paint mark in the drop-center. Others cut the valve stem hole at the lowest point of the rim.

If we are familiar with the rim manufacturer’s method of marking their rims, mounting the tire stiff spot aligned with the rim low spot is our preferred method. If not, we match the yellow circle to the valve stem to reduce the amount of weight we’ll need to add during the wheel balance.

If RFV turns out to high after mounting, we can use the GSP9700 to optimize a tire on a rim, or even several tires across several rims to find the best possible wheel combination. We can now provide our customers with the same level of wheel perfection once only available at the OEM level.

What could cause a car to pull even after an alignment?

Sometimes the sidewall on one side of a tire has stiff spot or spots, but the other side does not. This will result in the side with the stiff areas having a larger diameter than the other side when the stiff areas are between the rim and the road. This will make the tire cone shaped and cause it to roll towards the side of the sidewall with the smaller diameter and away from the side with the stiff spot.

This is called conicity. Conicity can also be caused by uneven tread wear, as might happen if the camber (lean) of the tire was incorrectly set on the car’s suspension. However, conicity is more often caused by stiff areas in the sidewall, and just like road force variation (which in essence it is, just on one side only) it often cannot be measured on an unloaded tire. Once again, the imaginary sidewall springs may all be the same length but compress at different pressures.

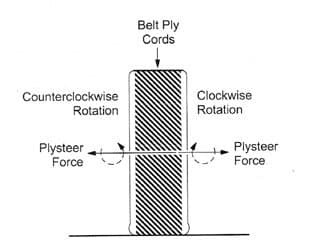

Plysteer

Plysteer sounds like something that would cause a tire pull — doesn’t it? However, plysteer usually causes more of a lateral (sidewards) shift in the rim position in relation to the tire tread than an actual pull. It can cause a bit of “dog tracking” or “crab walking”, but the car will still go straight down the road. Plysteer is caused by the orientation of the belt ply cords in the tire, especially the on the outermost ply. The lateral force caused by plysteer will change directions with the direction of tire rotation, so its effects on can be calculated by testing loaded lateral force while spinning the wheel in both directions. Important stuff for engineers, but as mechanics and drivers, we can pretty much ignore plysteer.

IT MAY NOT BE NECESSARY TO REPLACE A LUMPY TIRE

For years I’ve incorrectly believed that “ply separation” is the cause of steering wheel wobble and tire pull, and I’ve been repeating this misnomer to our customers. I had always recommended that a tire with a wobble and pull be replaced, even if the wobble and pull went away after finding the tire pressure low, then filling it to the proper pressure.

Now I’ve found that Toyota, Honda, Nissan, Toyo tires USA, Michelin tires USA, and other companies say this is not always necessary. That in fact road force variation and conicity are normal up to a point, and with the proper equipment (or a lot of trial & error), the effects of RFV and LF can be reduced or eliminated. A tire that is causing a wobble or pull is not always “bad” or unsafe. With proper pressure and placement, the tire may still provide years of satisfactory service.

YOUR CAR HAD MORE THAN A WHEEL BALANCE WHEN IT LEFT THE FACTORY

Some new car manufacturers have used large industrial machines to do road force variation testing to match tires to rims, and lateral force testing to position wheel assemblies on their cars at the time of manufacture. The technology has finally come down in price enough for a high-volume tire installer to justify the cost of an in-house tester. And a machine able to produce results comparable to OEM level machines is now small enough to fit in our shop. We’re not a high-volume tire shop, but we’d like to be able to do quality work, and we don’t like to rely on other shops for sublet, so we bought the Hunter GSP9700, even though the monetary ROI will likely be very low for us.

Why should you want advance tire balancing and selective positioning?

Why would you bother rotating the tires to different positions to reduce or eliminate the effects of tires with lateral pull? Won’t the pull just come back the next time the tires are rotated? Isn’t swapping tires around to cancel pull just temporary fix at best?

Well, some tires are just plain bad, and need to be replaced. With the GSP9700, we can test to see if your tires are within acceptable tolerances. The idea here is not to hide bad tires through crafty positioning. The idea is to position good tires, that generate normal amounts of RFV & LF, in the best possible positions. For instance, if you had 4 tires, each with only 30% of the total acceptable lateral force, but through bad luck, we managed to position all four of them so they were pushing the car to the left, you’d 120% of the maximum lateral force, and a car that drifted to the left every time you took your hand off the wheel on the freeway.

RFV and lateral force can change over time

I believe the following statement provides the most compelling reason for owning a road force / lateral force balancer (or having your car serviced by a shop who owns one).

Tire conicity can change in magnitude and direction over the life of a tire. [1]

This means a tire generating marginally excessive lateral force that was moved to the rear of the car or paired on an axle with a tire with an opposite lateral force during one rotation, might have reduced, or even reversed, its lateral pull 6,000 miles later when it’s time for the next rotation. If not, the worst case is you got another 6,000 miles out of the tire before spending $100 – $200 for a replacement.

[1] Source: SAE (Society of Automotive Engineers) report J2047, Titled: Tire Performance Technology

A STAGGERING REVELATION

Rushing to replace a borderline tire may not solve all your pulling problems either. A new tire will be larger in diameter, even if it’s the exact same size and brand, due to new, unworn, tread. This creates a condition known as stagger. Stagger is the difference in tire diameter between the left and right tires on the same axle. Stagger will cause a pull to the side with the smaller diameter, kind of like conicity shared between two tires. Stagger must be accounted for when choosing the optimum position for the wheels on the car.

4 WHEEL DRIVE AND ALL WHEEL DRIVE CARS AND TIRE SIZE

Some full time all wheel drive cars like Subarus and Honda CRVs must have exactly equal sized tires to avoid damage to the transmission or differential. The GSP9700 also takes the guesswork out of evaluating whether the differences in a car’s tire sizes is cause for concern.

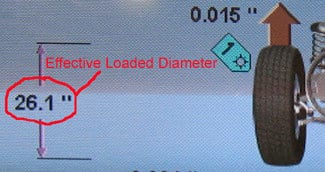

Subaru states all 4 tires must be within about 2/32″ of each other in remaining tread depth to prevent damage to the center differential. Honda, however, acknowledges that the loaded circumference of the tire is what’s important. After all, the weight of the car will be on the tire while it’s in service, and the loaded radius of a tire will typically be 1 & 1/4 inches less than the free radius.

A tire that is 24″ in free diameter, would have an effective diameter of 21.5″ when loaded. Trying to determine whether one tire is within 1/8″ of an inch in diameter of another, when it will be changing effective diameter by 3.5″ is impossible if your measuring tool is a tread depth gauge. Variables like the tire’s construction and load rating would not be taken into account.

Honda therefore recommends the following procedure. Put a dab of grease on the treads of all 4 tires. Roll the car forward until the tires have made a complete revolution. Measure the distance between the grease spots. Honda says there should no differences in the distance. However, there will obviously be no precision when measuring grease dab marks.A difference equal to 2/32″ of tread depth would show as about 1/3 of an inch in the difference in the distance between the grease spots. Smudge size and shape differences would likely mask anything smaller than that.

Effective diameter is a better metric than tread depth

The GSP9700 measures loaded radius, and calculates effective circumference using precision optical sensors in the loaded roller assembly

WHAT WOULD WE DO WITHOUT A GSP9700 TO BALANCE WHEELS?

So how did the automotive service industry ever survive without the GSP9700? Why weren’t cars veering off the road right and left? Some of you might be thinking, “I’ve been driving for years, and my cars have driven just fine as far as I’m concerned!”.

I’d guess 19 out of 20 cars have no vibration or pull problems after conventional tire rotation or alignment, and even fewer customers notice, or are concerned enough with the problem they come back to complain. A lot of people just get used to their car’s pulls & vibrations. However, for the customers who do notice and do care, we want to be able to fix their car without wasting a lot of time.

If a customer complained of a vibration or pull after a tire rotation, we would just swap tires back to their original positions. If a customer complained of a pull after an alignment, we would end up swapping from spot to spot until the problem was gone, or we isolated a bad tire through trial and error. What a pain! I’m sure a lot of our customers suspected we did something “wrong” during the alignment or balance, although most of them were too polite to voice their doubts about our competence. The problem was fixed when they came to pick up the car, and that seemed to be good enough.

Is it possible to correct tire vibration and pull without expensive equipment?

Can you muddle through tough tire problems without a GSP9700? Yes you can. We have for the last 27 years! However, you can produce a consistently superior repair in less time when you own this equipment, and we think it’s a worthwhile purchase. Even though we’ll never do volume tire sales like Costco or Big-O, we want to make sure are customers are not missing out on anything when they buy tires here, so we spend money on the best equipment, carefully research and test the product we sell, and stay up to date on training.

WE’RE HOPING OUR CUSTOMERS WILL SEE THE VALUE

We’re hoping our customers will appreciate being able have almost any problem with their car fixed here, without having to go to one shop for one repair and another shop for something else. The GSP9700 is yet another way we’re trying to make sure every service we offer is on par with the industry leaders specializing in that service.

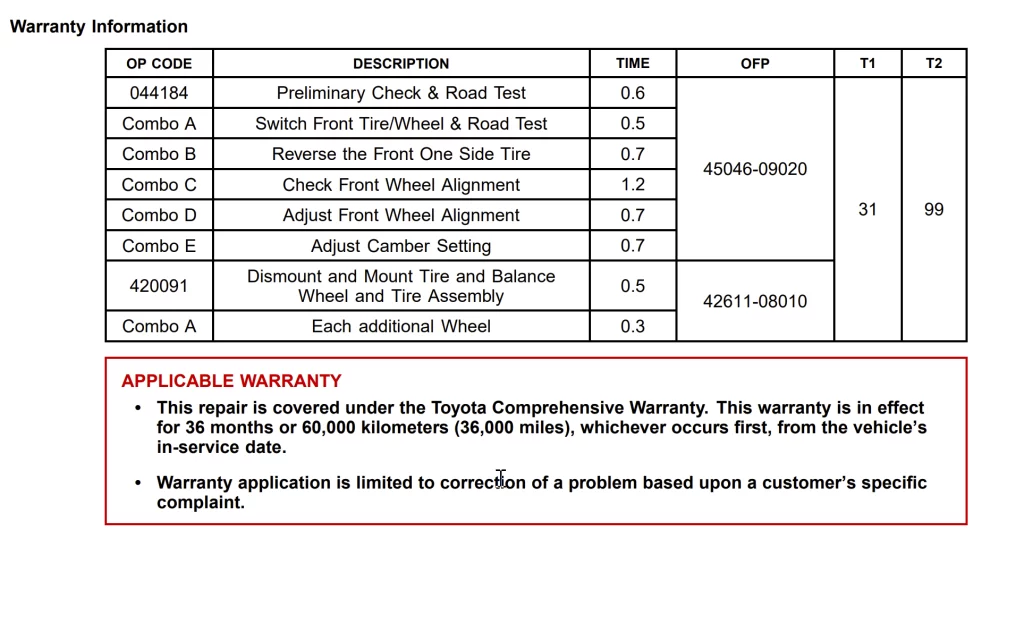

Toyota has issued a Technical Service Bulletin (TSB# ST005-01) outlining a procedure for diagnosing the cause of pull. It includes a number of wheel position swaps, reversing the mounting of the tire(s) on the rim(s), standard aligning, and / or installing modified adjusting bolts and doing a custom alignment. If there are no bent suspension or steering parts, Toyota will pay a dealer tech up to 5.2 hours to identify and repair the cause of a pull on car under warranty (and most mechanics know it’s not easy to beat the clock on warranty labor times). By using the GSP9700 road force measurement system and DSP600 alignment system, we will be able to do the same thing within 2 hours, every time.

How we balance tires

As soon as we started to use the GSP9700 for balancing new tires, we started to find problems we would not have found previously. One of the first things we noticed was that just because both beads “pop” while inflating to seat the tire on the rim, and the tire appears to spin true on the balancer, it does not mean the tire is properly seated.

We previously followed Toyo Tire’s recommendation that tire lube be used sparingly. Toyo says excessive lube can allow the tire to rotate on the rim, and affect the tire balance. Hunter Engineering says to “use lots of lube on the rim and the bead surface of the tire” to allow the tire to seat properly.

After we found a few freshly installed tires with excessive RFV that was corrected by dismounting and lubricating the rim and bead, then re-seating (with no change of tire position on the rim), we decided to go the “more lube” route. We recommend our customers avoid heavy acceleration or braking for the first 500 miles after tire installation. If a tire does slip on the rim, we will re-balance it at no charge. So far, we’ve not had any problems with slipping.

Balancing tires nearly as quickly as a standard wheel balancer

A basic balance and RFV & LF measurement can be done on the GSP9700 as quickly as on any other balancer. We do this with all new tire installations to verify proper seating and to check for rim problems. The procedure is simple, set the tire pressure, mount the wheel to the spindle and close the hood. Inputting rim size, width and offset information is only necessary if there is a problem with balance, RFV, or LF.

If there is a problem with balance, the inputting of rim data is far easier than it would be with most balancers. Just touch the rim with the data arms and step on the pedal. No need for calipers, depth gauge, or checking the sidewall for the rim size.

Measuring RFV and lateral force

Balancing is done with knowledge of the RFV, so real world balance “feel” can be much better than with a conventional balancer. In fact, a conventional balancer may say a tire balanced with the GSP9700 is out of balance, and if it were not for the effects of road force, it would be right, but because the car will be driven with the wheels on the ground (hopefully) the GSP9700 balance will be superior in the real world.

In addition to the normal balance measurements taken at the spindle, the GSP9700 uses a roller attached to a pneumatically actuated arm to apply pressure to the tire. The arm also has a very precise sensor that measures road force variation. The RFV sensor results are repeatable to within .001″, even when I tried to trick the machine by removing the wheel from the balancer then checking the same wheel again after a few other wheels had been balanced. While the roller is applying load, another sensor at the end of the spindle is measuring the lateral force being generated by the tire for the StraightTrack feature.

Handling modern wheel weights

With aluminum wheels and low-profile tires showing up on more and more late model cars, “tape weights” are necessary for about half the new cars we see. Working with tape weights can be frustrating with conventional balancers because the weights cannot always be installed where the balancer assumes they will be. This is due to the differences in design from rim to rim.

If you’ve ever had the experience of installing tape weights right where a balancer tells you to, then finding the wheel does not balance as you do spin after spin, adding weight after weight, until you have a wheel that’s a half a pound heavier than it was when it came in, you’ll know what I’m talking about. The GSP9700 lets the user tell the balancer where the weight will fit during set up using the dataset arms. Then it will guide you back to the spot you chose, just in case you forgot. This makes the job easy. Spin once. Add weight. Check spin. Done.

Some customers don’t like to see ugly lead weights on their fancy rims. We don’t do a lot of fancy rims and tires; most of what we work on are daily drivers owned by the grocery getting and back and forth to work crowd. However, if we need to balance the occasional set of $4000 rims and tires for an owner who cares what the inside of his rims look like, we can now offer a spilt weight placement to hide the wheel weights behind the spokes. We just enter the spoke positions into the GSP9700 with the inner dataset arm, and it figures out how to hide the weights out of sight.

Correcting RFV force

If there is a problem with the RFV, the user will be prompted to measure the rim for runout. Once again, a very easy task with the data arms. Just touch the data arms to the rim and press the pedal. The balancer rotates the tire and measures the runout. The rim runout is compared to the total wheel runout. If the rim is excessively out of round, a new rim is recommended. If the tire is the source of excessive RFV, a new tire is recommended. If both the tire and the rim have some runout, but neither is excessive by itself, the GSP9700 can help correct the problem.

Force Matching can be used to position the tire on the rim to minimize total road force variation. After measuring the rim runout and the total RFV for the wheel, the servo motor rotates the wheel so that the tire’s “hard spot” is at “12:00”. The tire is marked with chalk. Then the servo motor rotates the wheel so the rim’s low spot is at “12:00”, and the rim is marked with chalk. The tire is then removed from the rim, rotated so the marks line up and then re-seated The wheel is then re-tested to measure the improvement. The GSP9700 calculates the expected RFV improvement so the user can decide whether it’s worth the time to reposition the tire on the rim.

Force Matching can also be done across a set of 4 rims and tires. This provides a way to improve RFV when one or more wheel assemblies can not be brought within limits by Force Matching with only one tire and rim. 4 wheel assemblies and rims are measured and marked, then the computer

Correcting lateral force and tire pull

StraightTrak is Hunter’s lateral force measuring system. We are using it in combination with a 4 wheel alignment to guarantee a car will not pull after the service (providing, of course, there are no bent suspension parts or a out of limit tires or rims). The GSP9700 uses lateral force measurement, loaded radius, and RFV measurement to develop a “Vehicle Plan” with optimized wheel placement to reduce vibration and pull.

The Vehicle plan can be formulated for minimum vibration or minimum pull. Alternate placements can also be explored if the tires are directional or it’s desirable to keep axle sets together due to wear or brand. We realize not everyone will want to pay for 2 hours for an alignment and StraightTrak, and that’s fine. We’ll still be doing stand alone alignment for those who want it, with our normal disclaimer that tires can cause a pull too.