I had a first-time customer call in the other day and ask how much it would be to figure out why her car wouldn’t start even with a good battery. She said she had replaced the battery and then the car started, but the next day when she tried to start the car, it just made a clicking sound and the dash lights flickered. Later she got a jump start and she was able to start the car, but it wouldn’t restart after she turned it off.

Car Won’t Start? How Much Does it Cost.

I told her we charge a flat fee for the first hour of inspection, and additional charges may apply depending on the complexity of the issue. When the issue is simple (a bad battery for instance) we reduce our fee.

And then she asked, “OK. What do I get during the first hour inspection? Is there something on your website that explains it?”

First off, that was a very good question. When people take the time to communicate and find out exactly what their expectations should be before starting a project, it’s good for everyone involved. But no, there wasn’t an explanation on our website, and now I’m correcting that.

Charging / Starting Inspection

On our repair order there’s a job description that says:

BASIC STARTING / CHARGING SYSTEM INSPECTION:

(Additional testing may be needed, such as voltage drop testing, or finding the source of key-off current draw.)

STATIC VOLTAGE _____V

DID WE RECHARGE THE BATTERY? _____YES _____NO

BATTERY LOAD TEST _____V @ _____A

LOADED CHG VOLTAGE _____V

KEY OFF DRAIN _____mA

But what does all of that mean? It does define what’s included if you already know a bit about testing starting and charging systems, but for a lay-person it’s not very informative.

Here are some of the symptoms you might experience when there’s an issue with the starting or charging system.

- The car won’t start (no crank) when it’s cold

- The car won’t start (no crank) even with a good battery

- The car won’t start (no crank) even with a jump start

- The car won’t start (no crank) and it’s making a clicking noise

- The car won’t start (no crank) after sitting for a while

- The car loses electrical power while driving

- Nothing happens when you turn the key to the start position

- None of the dash lights light up and the car won’t start

Car Won’t Start? How we Find the Cause.

And here are some of the problems that can cause these symptoms and some information about the testing we perform to find your starting issue.

“Dead” battery

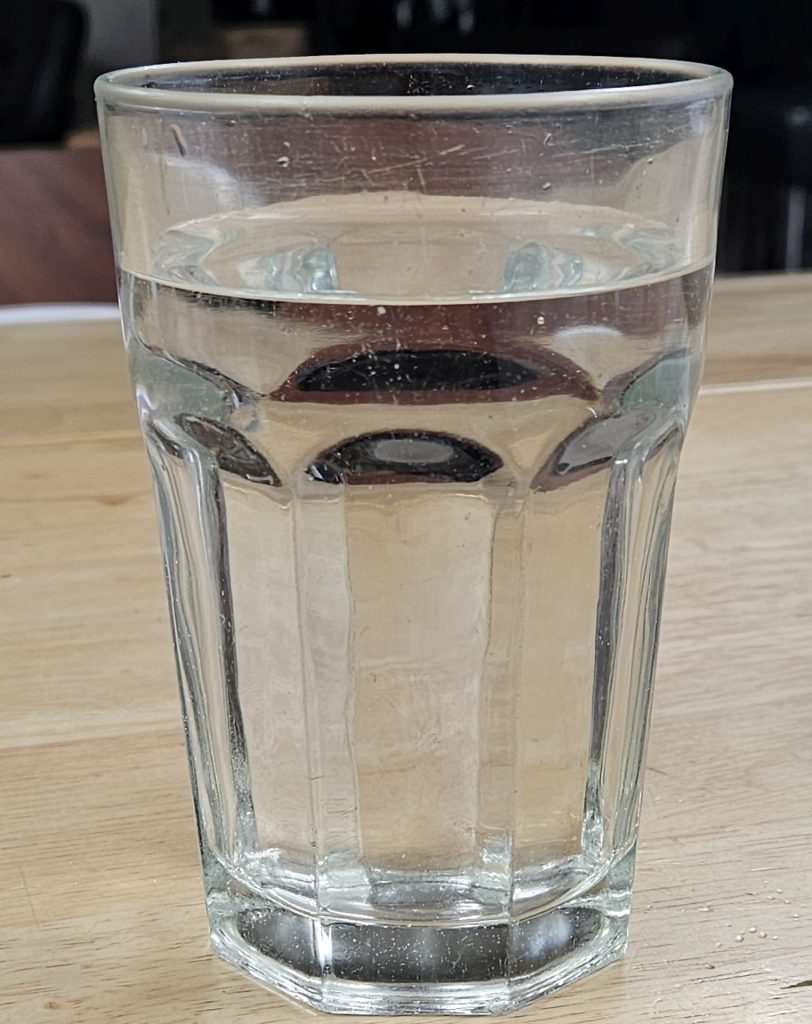

A “dead” battery can be one of two things: a battery that’s bad, meaning incapable of taking or holding a charge, or, it could also mean that the battery is discharged. I like to use a “glass of water” analogy. A full glass of water is like a good battery. If you make a mark on the cup near the top of the rim and fill the cup to that line, you could think of it like a fully charged battery. It’s holding about as much water as it can. A bad battery on the other hand can’t hold enough water, even if you try to fill it.

Discharged battery

If the battery is discharged, it’s like an empty cup. There’s nothing wrong with the cup, you just need to add some water. Similarly, there’s nothing wrong with a discharged battery, you just need to recharge it.

One of the ways to gauge a battery’s state of charge is to measure its voltage. Voltage is electrical pressure, and it’s much like the water level in the cup. When the cup is full the pressure at the bottom of the cup is high. This could be demonstrated by poking a hole near the bottom of the cup. If the cup were full, a strong stream would flow from the hole. If the cup were near empty, water would trickle weakly from the hole.

Bad Battery

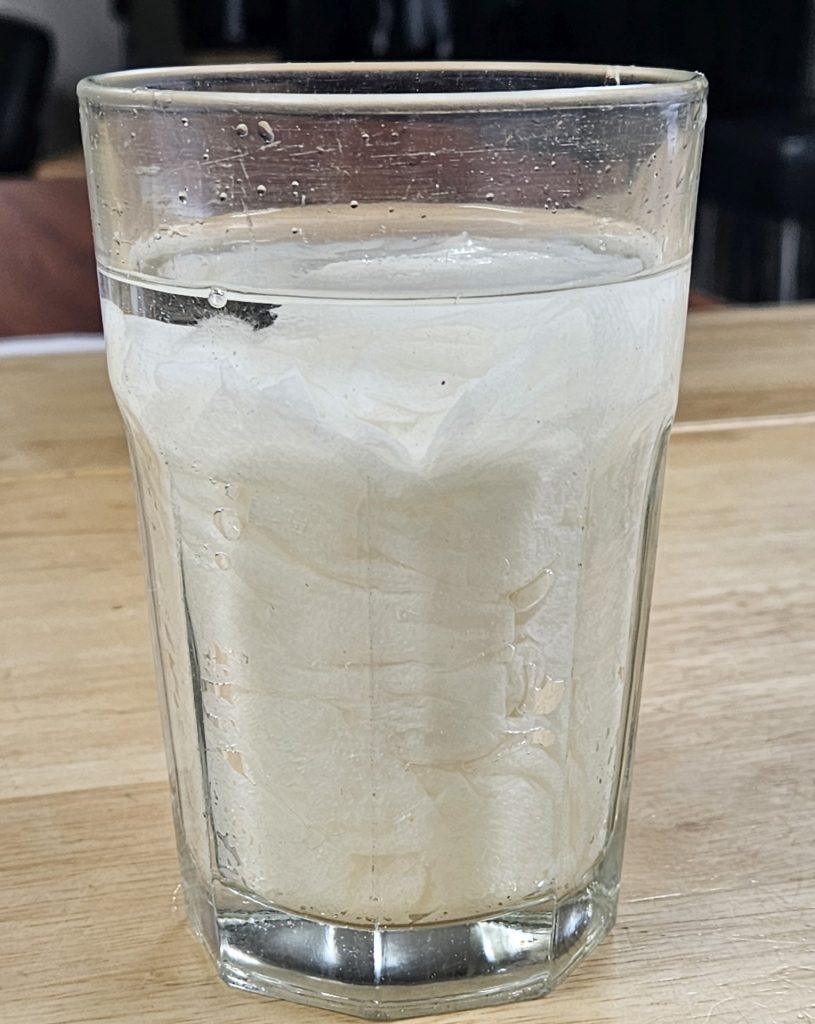

A bad battery is like a cup that’s packed with some gravel or other material that takes up space and reduces the amount of water that can be added to the glass. You can fill the glass up to the line, but it’s not holding much water due to most of its capacity being filled with little rocks. Recharging a bad battery won’t fix it, you need to replace the cup with a new gravel-free cup.

When you charge a bad battery and look at the “static” voltage, it will usually look good. “Static” just means the battery is sitting there doing nothing. It’s not turning the starter or powering the headlights. After you charge a bad battery, the static voltage will usually be normal – about 12.7 volts. However, if you try to draw current from the battery, it can’t maintain voltage, just like the stream from the gravel filled cup will quickly weaken due to the low volume of water in the cup. This is why a bad battery usually won’t be found with voltmeter alone. The cup can be filled and will look full, but its low capacity will cause problems when the battery is used.

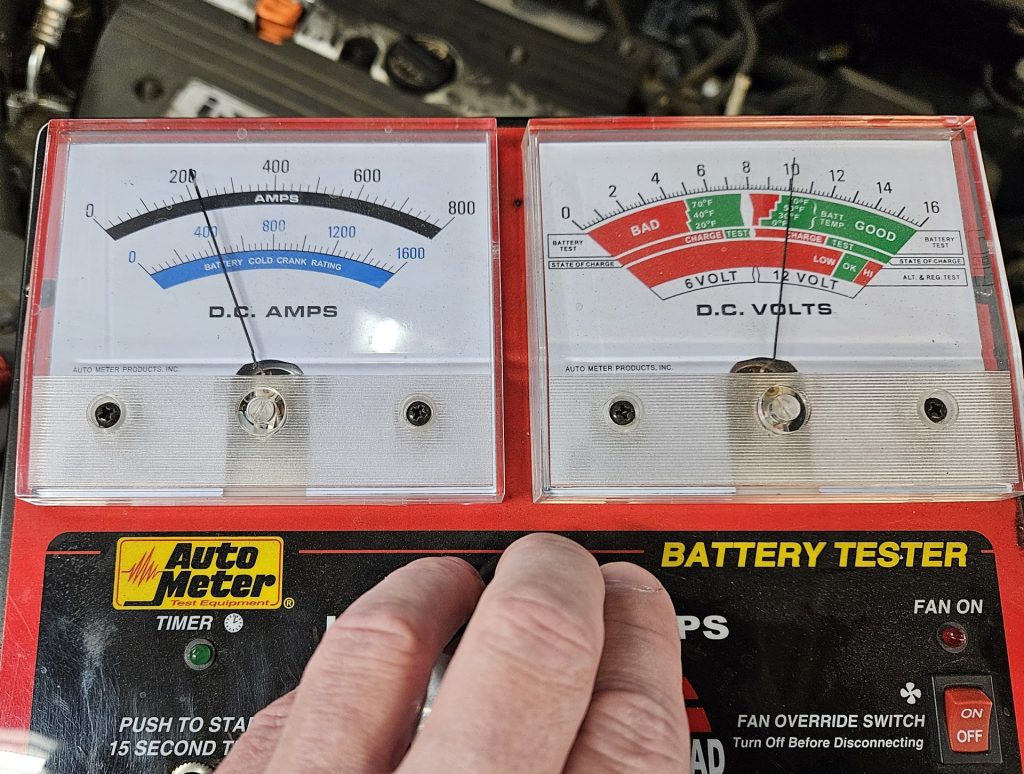

Load Testing

The best way to find a bad battery is load testing. When we load test a battery, we pull a lot of current from the battery to stress it and then measure its voltage while it’s loaded. The static battery voltage may look fine, but once a load is applied the voltage will drop below what’s normal if the battery is bad.

Load Testing Rules

Batteries are rated is several ways. One of those is “cold cranking amps” or CCA. When load testing, a load of 1/2 of the CCA rating is applied to the battery. We use a variable resistor draw current from the battery while monitoring the current flow using an ammeter (a tool that measures current flow).

We twist the dial until the current flow is 1/2 the rating, and then we hold it there for 15 seconds. Assuming that the temperature is 70F, the battery voltage should drop no lower than 9.6V. If the temperature isn’t 70F, then the “pass” voltage will be different. Batteries tend to work better when warm.

A battery must be at least 3/4 charged when load testing. If it’s not, the load test may fail even though the battery is good. Likewise, it’s possible for a battery to pass a load test when it shouldn’t if it’s tested immediately after charging. Often mechanics will load test a battery, let it rest for a while, then load test it again to avoid false results after recharging.

Internal Resistance Testing

A different method of testing batteries has become very popular in recent years. A computerized tester pumps a signal across the battery and measures what comes out. There are some good things and bad things about these testers.

Good things:

- They’re idiot proof. No skill or knowledge is required to use these testers. Auto manufacturers love them because overall they reduce undeserved warranty claims. You’ll find them used at every dealership.

- They can test a battery when it’s not 3/4 charged

- They’re hand-held and very portable. Great for tow trucks.

Bad things:

- They give incorrect results frequently. They’ve eliminated human error and replaced it with machine error. They’re likely to return a false “bad” result when the battery is discharged. When the battery is fully charged, they’re likely to return a false “good” result.

If the mechanic performing the work is competent and takes the time to properly charge the battery, compensate for temperature, test the battery at the correct load, wait the full 15 seconds to take the voltage reading, and takes surface charge into account, a load tester is a far superior tool.

Charging System Failures

Sometimes the battery isn’t the source of the trouble at all. It may be discharged, and the engine may not crank, but it’s not because the battery is bad. It’s just an empty cup that needs to be filled. Every time you start your car, you use some of the power stored in the battery to turn the starter motor. The charging system puts that power back into the battery so it’s ready to start the car next time. It also powers all electrical load once the car is running. Lights, wipers, ignition, etc.

If you have a conventional car, the heart of the charging system is the alternator (which some engineers will call a generator, but that’s a long digression beyond the scope of this article). The alternator generates voltage at a level at least 1 volt higher that the battery’s static voltage. Typically 13.5V – 14V for most of the cars we repair. Testing is pretty easy. We check the voltage output. If it’s OK, we load the alternator and verify that it can still charge the battery when demands are high.

Some older cars had alternators with a separate voltage regulator and/or rectifier, but these days everything is housed in one unit. However, a bad alternator isn’t the only possible cause of low charging system voltage. The car’s computer can control the alternator’s output on most modern cars, so if the alternator isn’t charging, the computer’s command and wiring must also be checked before condemning the alternator.

Key Off Drains

Another problem that can cause a “no-crank” is a “key off drain”. This just means something drained the battery while the car was parked. If you’ve ever left your headlights on overnight, you’ve likely had first hand experience with key off drain. Drains can range from simple to complex. We’ve had many cars come in with discharged batteries and as soon as we connect a booster pack, it’s obvious the map light was left on.

Other times it’s not so simple.

Measure the drain

The first step is to measure the current (flow of electricity) leaving the battery. All cars have some key off drain. It’s necessary to keep the body control unit awake so the doors unlock when you press the button on your remote. It also powers computers so they can “remember” what they’ve learned. Most cars pull between 15 and 50 milliamps (mA) of current, and this is normal. If you leave a car sitting much more than a week, it may have problems starting.

Make sure the drain isn’t temporary

So, what happens if we find a drain of 315 mA? The first thing is to let the car settle down. Many control modules “stay awake” for a while and talk to each other on the network. A modern car will have somewhere around 30 computers connected via several networks. If they’ve been active, they’ll stay active or a while so they can respond quickly and do your bidding without any perceptible delay. If they haven’t been active for a while, they’ll settle down. Instead of checking for input every 200 milliseconds, they’ll check only once per second. This will reduce their power consumption around 80%. On some cars it may take 30 minutes for the key off drain to drop to it’s normal level.

Find the source of the drain

If it doesn’t, well, this is one of those times it will cost you more than the original 1/2 hour charge. We’ll monitor the ammeter while pulling every fuse, one at a time, until the key off drain drops. This process can be time consuming because putting a fuse back in often “wakes” a control unit, so we must wait for the car to go back to sleep to resume testing.

One fuse will eventually cause the drain to drop to a reasonable level. Once this happens we’ll check the service manual to find out what the fuse powers. A single fuse can power one load or 20, so sometimes it’s easy to find the issue, other times it’s hard. We disconnect connectors wherever the circuit splits while watching the ammeter to track down the draw. It’s really easy on paper, but often very difficult in practice. Electrical connectors live under dashboards, carpet, or body panels. When we track down a key off drain, this is what you’re paying for.

Starting system problems

We’ve covered bad batteries, and discharged batteries which can be caused by a problem the the charging system or something draining the battery. The final thing to check is the starter. A starter can have the following problems:

- The starter motor doesn’t have power or enough power

- The starter motor isn’t getting the electrical signal that causes it to engage and spin

- There is an electrical problem with the starter, like a bad solenoid, brushes, or windings.

- There’s a mechanical problem with the starter like bad bearings

Power

The battery cables go more or less straight to the starter. When the starter is engaged, there should be almost as much voltage at the starter as there is at the battery. The battery cables “eat” a little of the voltage. If a starter is spinning slowly or not at all, we’ll test the cables to see if they’re eating more than their share of voltage. This is called “voltage-drop” testing. We’re measuring how much the voltage drops between the battery and the starter.

Start signal

When you turn the key to the start position, voltage is sent to the starter solenoid. This is an electromagnet built into the starter that does two things. One, it moves the starter pinion gear so it connects with the ring gear attached to the crankshaft of the engine. Two, it connects the positive battery voltage to the rotor windings so the starter will start spinning. We check to make sure the start signal is getting to the starter if the starter won’t spin at all.

Starter electrical problem

We infer an electrical problems with the starter. If the starter has good voltage at the battery cables, and it gets a start signal, and it doesn’t spin, it must have an electrical problem. We used to do a lot of starter repair here at Art’s, but those days are long gone, so we don’t diagnose any further than that. If a starter isn’t working, we order a new one.

Starter mechanical problems

A starter has bearings and bushings that can fail. If a bearing fails, the starter is hard to spin. This can cause it to spin slowly or not at all. The way we diagnose this type of problem is to measure the amperage the starter draws. A normal current draw might be around 160 amps or so. A starter with worn out bearings might pull 400 amps or more.

Still reading? Thanks for taking the time! Educated customers make our job a lot easier, and we’re always happy to explain what we do to anyone who’s interested.