The other day a “front brake light switch” message appeared on my 1290’s display. It’s still a pretty new motorcycle. It might even still be under warranty since it’s a 2021 with about 5,000 miles. Anyway, it seemed like it would be a small issue, and I’m a mechanic, and the dealership is far away, so I figured I’d fix it. Now I’m sharing what I found in case you’d like to fix yours.

I have the service manual, which is surprisingly sparse compared to automotive service information. I’m guessing dealerships have electronic service information systems with additional information. After looking at the wiring diagram, my first question was, “How does the control unit (MCU) know that there’s an issue with the brake light switch?” The switch is a single two-wire non-redundant switch. A quick check of the brake light function revealed it still worked, even with the switch unplugged. That means that there must be a pressure sensor in the ABS actuator that measures pressure from the front master cylinder. Many cars are set up that way.

Started with Google

No need to reinvent the wheel. A search for 2021 KTM Super Duke 1290 front brake light switch message brought me to a KTM forum where people said they fixed the issue by cleaning the switch.

Um, no they didn’t. The switch is an Omron microswitch with the markings AQ 09Y9N4 A201, and it’s WAY too tiny (and melted together) for successful repair. (And I do a lot of electronics repair work under a microscope.) But I tried anyway, first with some Deoxit past the switch plunger, then by trying to disassemble it. Was it even bad? Well, it was after I got done trying to disassemble it!

Where to Get a new Switch

A KTM dealer will order a switch for you. Its part number is 61311050000. I ordered one from K&B Motorsports in Petaluma (a good KTM dealer), but it was a week away and the brake light message on the display was annoying me and I can be impatient.

KurveyGirl has Brembo switches that will work. I bought a switch that will function as normally open and normally close depending on how it’s wired (110A-SWITCH-OPEN).

Normally open and normally closed can get a little confusing. For the 2021 Super Duke, the switch is normally open in the diagram. However, you’ll need to buy a normally closed switch. Here’s why that makes sense. If the switch isn’t installed on the bike, and you don’t press the plunger, the switch is closed, so it’s normally closed. However, when the switch is installed on the bike, but front brake lever is pressing on the plunger unless you squeeze the lever, so it’s normally open.

Anyway, the switch arrived two days later. This switch comes with a pigtail, so you’ll need to solder it into your existing wiring. I went ahead and installed it and…. the front brake light switch message comes right back. That’s annoying.

How to diagnose the Brake light switch properly

I suppose I could have stared with this step. And I were working on your car I would have. Anyway, here we are.

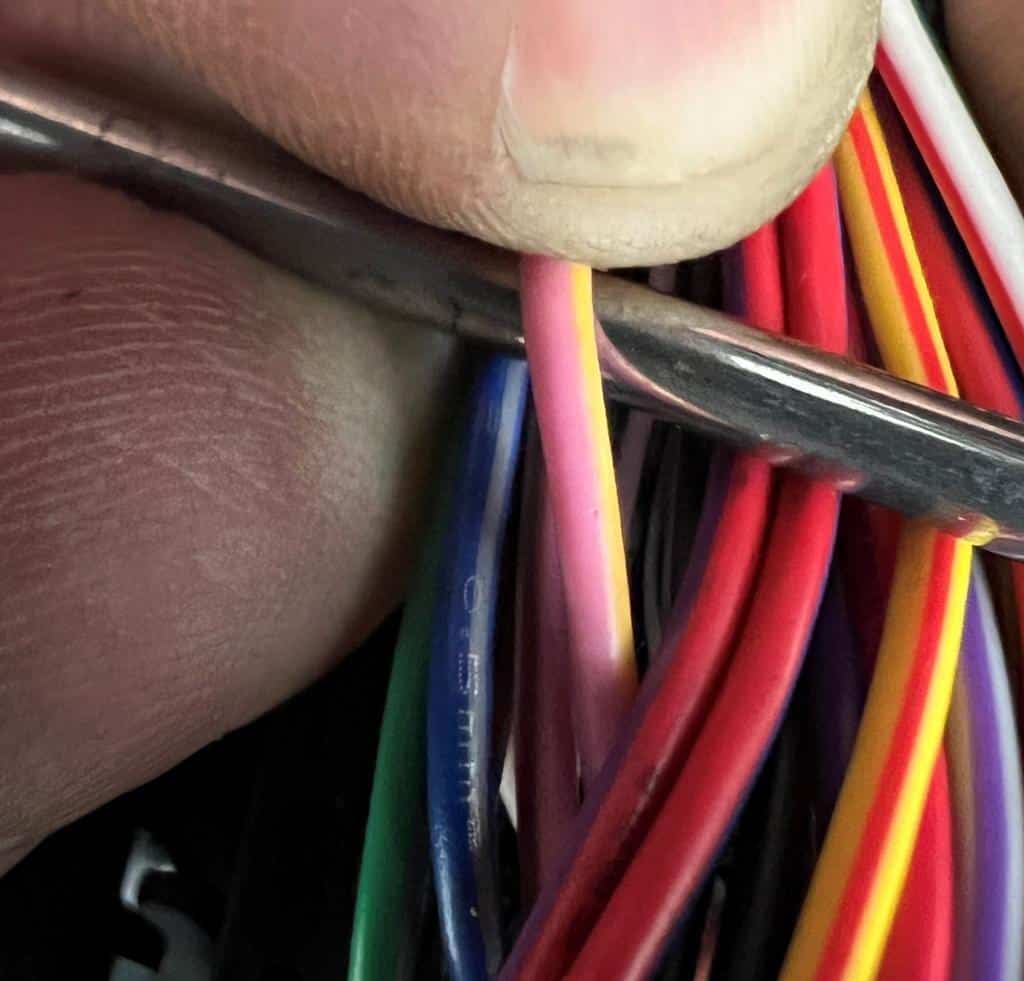

One of the switch’s wires goes to chassis ground. The ground wire is OK. (It’s actually not, but it tested ok.) The other wire goes to the MCU. I didn’t bother figuring out exactly what the MCU is exactly. Maybe a networked body controller? Anyway, after the switch connector the wire is pink / yellow. The wire was open when measured from the switch to the MCU connector.

Tug testing is a good way to find a broken wire. It’s pretty hard to pull apart a wire that’s in good condition, but if some or all of the strands are broken, you can break a wire without super-human strength.

The brown wire from the switch (which later becomes pink/yellow after the switch connector) pulled right out. I split the conduit until I found the end of the wire.

Why did it fail so soon?

This motorcycle is less than a year old with only 5,000 miles. Why did the wire break? Many will think it was poorly routed, causing a constant bend or tug, but that’s not it.

There are different types of wire. In your house, where nothing moves, you likely have single conductor wire. It’s stiff like a coat hanger, and if you bend it back and forth enough times it will snap, just like a coat hanger. In automotive applications all wires are multi-strand to allow for flexiblity.

Not all multi-strand wire is the same. A wire with more strands is more flexible than a wire with fewer strands. In areas that will flex, like the area between the frame and the forks, very flexible wire should be used. The best type of wire for this application is marine grade wire. This type of wire has flexible and heat resistant silicone insulation and many very fine strands of wire. In addition, the copper strands are nickel coated for corrosion resistance.

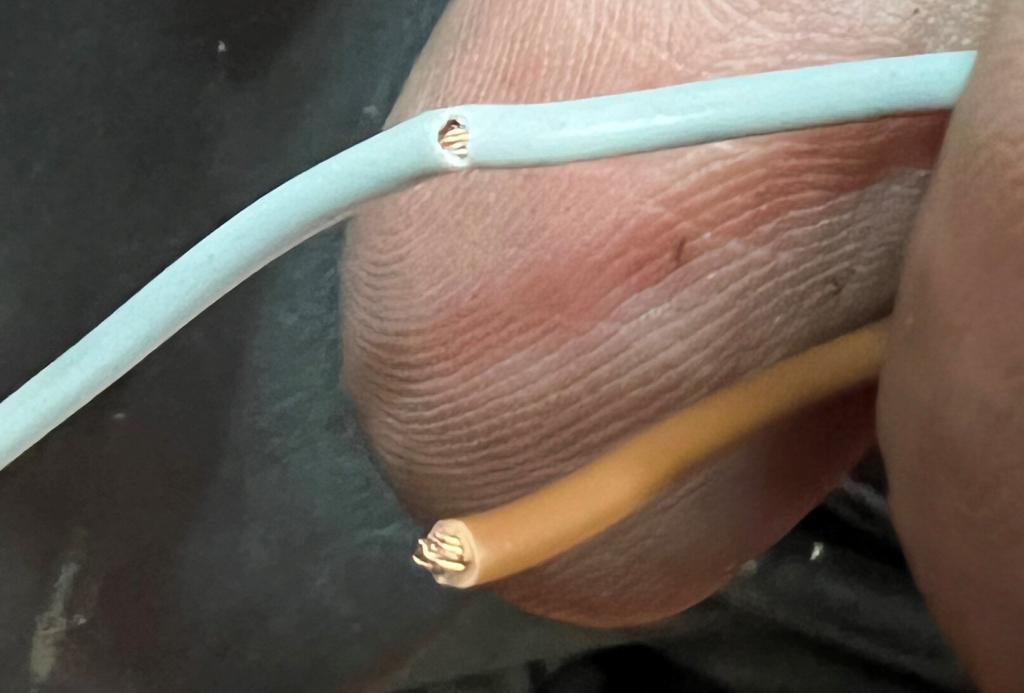

I bent both wires on the right into an “S” shape. Only the brown wire stayed in the shape due to its course strands and rigid insulation. This type of wire cannot be used in applications that flex.

Who’s fault was it?

Do I blame KTM? Well, sort of, but not as much as you might think. These wires come with the switch. The switch was chosen by Brembo for their master cylinder; it’s the same switch used on many Brembo master cylinders across many makes. So, is it Brembo’s fault then? Well, Brembo didn’t make the switch, Omron did.

So, Brembo should have specified fine strand wire when they spec’d out the switch with Omron. KTM should have done the same when they spec’d out the master cylinder with Brembo or kept the leads short and built a harness that went all the way to the switch so they wouldn’t flex.

Would I buy another KTM?

Absolutely. I love this bike.

If you’re interested in reading more of my articles (mostly automotive), here’s a link to some of them: