Sorry, but these Honda oil pan thread repairs aren’t available for mail order. We only sell them to customers having their cars repaired here at Art’s Automotive.

Honda oil pan threads have been trouble since 1984. Honda cars in general are very reliable, so their failure to fix this sore spot for so many years is a little confusing to us. Maybe they just want to make sure all the Honda mechanics don’t go out of business for lack of work.

The problem with Honda’s steel oil pans is that the drain plug threads are frequently damaged, and the drain plug sealing area tends to distort. Honda uses an aluminum sealing washer to seal the drain plug against the pan. Aluminum is fairly malleable as far as metals go, but still requires much more pressure to crush than do other types of sealing washers, such as fiber, rubber, or copper. Honda recommends 29 ft/lbs of torque on the drain plug to seal the washer – less torque and the washer will not seal, and you will find a puddle in your driveway the day after your oil change. The problem is the flimsy threads and thin sheet metal cannot take this amount of torque and will fail after repeated torque.

Who’s to blame

There is often a tendency to blame the last mechanic who changed the oil for damage to the threads. This is sometimes valid when you’re talking about a Toyota, Nissan, Subaru, or Mazda, but rarely is the case with an Acura or Honda. Honda drain plug threads are slowly damaged over time, and like a slowing roulette wheel, the buildup of thread damage can ruin any mechanic’s attempt at an oil change at random. Some mechanics will try to avoid bringing the subject up (and potentially bringing the blame on themselves) by sticking the drain plug in with a glob of silicone sealer and hoping the next oil change is done somewhere else. We believe it’s important to alert you to the problem at the first sign of trouble. A planned oil pan repair or replacement is preferable to an emergency oil pan replacement at an inconvenient time.

Repair options

Replace the pan with an OE pan

This is was the only choice for a long time. It works, but the original design flaw has not been addressed. The new pan is likely to last about as long as the last one did.

Use a fiber washer

Toyota has used fiber washers for years. Toyota’s current generation of oil pans never have drain plug or oil pan issues. If your pan has only mild thread or sealing surface damage, using fiber washers can buy some time. The problem with fiber washers is they will frequently get switched back to aluminum washers with the next oil change. A mechanic will see the fiber washer on a Honda and say, “Hey, that’s the wrong kind of washer; I’ll fix it” as they put an aluminum washer in its place. Also, many shops will not have a supply of 14mm fiber washers, since they are not original equipment for any car that I know of.

Use a Sure Seal Plug and o-ring

A company called Sure Seal came up with a couple good aftermarket redesigns for Honda products. One of them was the Sure Seal drain plug. Click for more information or to order. The Sure Seal drain plug has a groove in the sealing surface to allow for the use of a rubber O-ring. Rubber is very malleable and can form to the shape of a fairly distorted sealing surface and requires very little torque to seal. The problem with the Sure Seal is much the same as with the fiber washer — a mechanic lacking knowledge of the product or replacement O-rings will replace the Sure Seal plug with a Genuine Honda plug and washer during an oil change.

Repair and improve the oil pan design

This is our latest offering for Honda oil pans. One day I called the local Acura dealer and asked for an oil pan for an Integra. They asked, “new or rebuilt?”. I’d not heard of a rebuilt oil pan before, so I asked about it. They said they have a supplier that repairs oil pans for them. I asked how much, and they said, “same price as new, but these are much stronger”. I thought about it for a second and realized how easy it would be to improve on the design. Why not build oil pans here at Art’s. By doing the repair in-house, we could sell the pan for less than the new one would cost and offer quality a solution to Honda’s oil pan problem. It also fits well with our environmental philosophy… what would be another piece of scrap metal is put back into service.

About our oil pan repair

Our rebuilt oil pans have a thick sealing surface made from a hardened carbon steel washer. This washer is 250% of stock thickness and that will not distort at a torque far greater than the 29 ft/lbs necessary to seal. The threads are made from a grade 8 nut and have 400% more contact area than stock threads. This nut could handle well over 100 ft/lbs of torque if used with a grade 8 bolt (which the drain plug is not). Applying the torque necessary to seal the drain plug is no longer a problem, the oil pan would crumple long before the threads would fail.

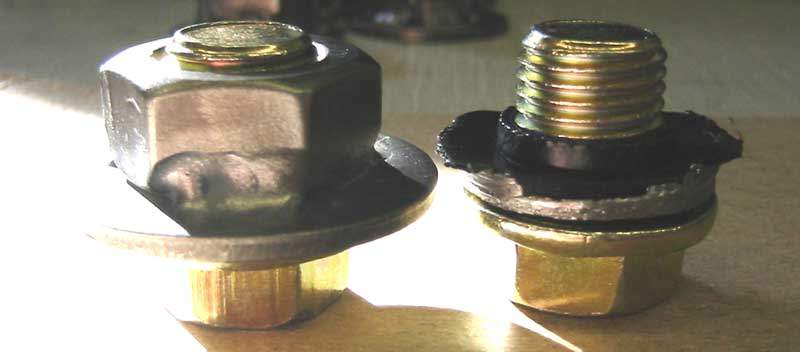

This is a picture of the thread insert we TIG weld to the oil pan (on the left) and the threads that original stamped threads we cut out from an oil pan (on the right). It doesn’t take a mechanical engineer to see the replacement is a whole lot beefier than the original. 6 of 8 drain plug threads are showing (and therefore doing nothing to add to the strength) on the stock pan’s bung, whereas only one thread shows on our replacement bung.

After the replacement bung is prepared, the old threads are removed from the oil pan using a bi-metal hole saw and a centering jig. Then the paint is sanded off and the metal is cleaned to remove contaminates that might cause a porous weld.

The upgraded Honda oil pan threads bung is TIG welded to the oil pan for a non-porous leak-free joint.

Honda oil pan threads better than new

After checking for leaks, the pan is then hot tanked and painted. A new plug and drain washer are installed and it’s ready for service.