This is the story about a repair to 2001 Prius hybrid transmission. It had developed a problem with MG2 inside of the transmission. The MG2 is the larger of the two electric motors in the HV transaxle assembly. We’ve replaced two hybrid transmissions in the past, but this is the first Prius hybrid transaxle we’ve disassembled and repaired in-house

The owner of this car called us for a quote on replacing the HV transaxle after a Toyota dealer had told her a new transaxle would be over $5000 to install. Unfortunately, we had to tell her the same thing; most of the cost of an hybrid transmission replacement is the hybrid transmission itself. I said we might be able to repair her hybrid transmission by replacing just MG2 instead of the whole transaxle, since both of the failed hybrid transmissions we had replaced were replaced due to high voltage leaks in MG2 (which sets a code P3009). She was willing to explore this possibility, and drove the car in so we could take a look.

The Toyota Dealer did a Good Job with the Diagnosis of the transmission

When she arrived, she had the dealer’s repair order which had an exceptionally well documented diagnosis of a bad hybrid transmission. However, the problem with this Prius transaxle was different than what we were expecting. It did not have a code P3009, “high voltage leak detected” as we had seen before. Instead it had a P3120 with an information code 250. Toyota Information System (TIS) states “If information code 248 or 250 is output, replace HV transaxle motor”. There is no other diagnostic procedure.

The dealer was considerate enough to leave the code and freeze frame data in place since they knew the car was going to another shop for a second opinion. (Freeze frame data, for those of you who might not know, is like a snapshot of relevant sensor data at the time the fault code was set, sort of like a flight recorder on a plane).

P3120 is listed as “HV transaxle malfunction”. The sub-code 250 indicates a “Motor temperature sensor performance problem”, which is a little ambiguous. Is the problem with the actual temperature of the motor, or is the problem with the sensor accuracy. I had initially figured, with the help of many on IATN, that the sensor was likely reading out of range. Freeze frame information indicated the temperature problem was with MG2. I have now deduced that the code was likely caused by the actual temperature of MG2, rather than an MG2 temp sensor reading out of range.

Working as a group

IATN, by the way, is “The world’s largest online community of automotive professionals”, and is a great place to find out if another mechanic has already struggled through the same problem you are having. Since the official Toyota diagnostic procedure was somewhat brief, I posted to IATN to see if anyone had any ideas.

Most of the discussion on IATN focused on the temperatures of the MGs (the electric motor/generators) when compared to the temperatures of the inverters for the motor generators. The inverters, for those of you who might not know, provide the pulsed power that drives the MGs.

The conclusion of the discussion was that if the temperature of the MG2 motor temp sensor was high, the cause would likely be a mechanical problem such as a seizing bearing. The bad bearing’s extra resistance to spinning would increase the electrical power necessary to turn the motor. The inverter that drives the motor would then get hotter because it had to do more work. So if the MG2 was the cause of the high MG2 temp sensor reading, the MG2 inverter temp sensor would also read high.

This is some of the freeze frame data from when the code set:

The MG1 motor temp was 152 deg. F

The MG2 motor temp was 320 deg. F (clearly too hot!)

The MG1 inverter temp was 107 deg. F

The MG2 inverter temp was 91 deg. F

Our theory turned out to be wrong, but it didn’t matter

Since the MG2 motor temp was smokin’ hot and the MG2 inverter temp was cooler than the MG1 inverter temp, the assumption was that the MG2 motor was not really overheating, but rather the sensor was simply not accurately reporting the MG2 motor temperature to the HV control computer.

It’s a truly excellent theory, which, unfortunately, seems to be incorrect. Luckily, it makes no difference for the real world repair since the MG2 temp sensor can not be replaced without ruining the MG2. So there’s only one transmission repair option for this hybrid. Whether the problem is the MG2 temp sensor or the MG2 motor, we’ll need to replace the MG2 assembly to fix it.

After we decided the problem was probably the MG2 temp sensor, or perhaps the MG2 itself, and that either problem would be cured with a new MG2, we offered to do an MG2 replacement rather than a whole transaxle. And since the code had not reset for us during extensive test driving, we recommend the customer take the car and drive around for a while before we did anything. We changed the T4 fluid because we wanted a sample, and, “Hey. Why not? Couldn’t hurt”.

Making extra sure there was really a problem

Our customer reported doing a lot of driving, some in hot weather and up hills, with no Master Warning Icon. Then, after about 500 miles of driving, the Master Warning light came on during a relatively easy drive.

When she came back, the car had two new problems: the car shuddered when taking off from a stop when driving forward or in reverse (sort of like a lower frequency version of the Honda CVT start clutch shudder), and there was a new code — a P3009! This is the code we originally assumed we would find when we heard it had been diagnosed as a bad transaxle.

The hybrid transmission repair begins

Before we could go ahead with the planned hybrid transmission repair, we needed to be sure the P3009, “High Voltage Leak Detected” code was also caused by the MG2, as we had seen in the past, and was not caused by something else, such as a bad cable, inverter, or MG1. So we did the standard checking and found the MG2 was shorted to ground, and MG1 was not. Was the judder also caused by the MG2? It’s impossible to say for sure, but we figured the probability was very high, since we knew there were at least 2 known problems with MG2. If there were another transaxle problem causing the shudder, it was likely we’d be able to find it once the transaxle was apart. So after getting customer approval, we started to tear it down.

To repair the hybrid transmission, the engine and transmission must be removed together. The whole assembly drops out the bottom of the car once everything is disconnected and out of the way.

Then Scott, AKA “Mr. Prius”, separates the engine from the transaxle. One of the things Scott noticed right away was the strong smell of burnt transmission fluid. The fluid had smelled sweet, like transmission fluid ought to, only 500 miles ago, and that was *before* we changed it. This, coupled with the new judder and P3009, are the reasons I now believe that MG2 was really overheating, rather than the MG2 temp sensor malfunctioning.

Once all the bell housing bolts are removed, an engine hoist is used to pull the transmission away from the engine.

The HV transaxle is very heavy, and each half of the transaxle has a large electric motor in it, so it’s not a good idea to try to lay the whole thing on a bench and split the cases. Toyota recommends using an engine hoist to raise the MG1 half, leaving the MG2 half on the ground.

There are special bolt on hooks available from Toyota that allow lifting at points that will keep the transaxle balanced so it doesn’t get cocked as it’s separating. This is a picture of our hastily fabricated alternative to the official tool, cut from a piece of rusty scrap metal. It’s not pretty, but it holds the transmission centered.

The Toyota instructions recommend poking a taped screwdriver in between the cases to hold the drive chain in position as MG1 is lifted. We found pushing down on the input shaft worked a lot better. Once the input shaft disappeared past the seal, Scott was able to hold the drive chain with his hand.

Once the cases are split, MG1 is laid off to the side, and we start removing and inspecting the guts from MG2, starting with the counter driven gear. We found no problems with the tapered bearings or teeth on the counter driven gear, just normal light wear.

Next comes the differential. The ring gear, carrier bearings, and pinion gears and shafts, are all OK. The differential, in case you’re curious, is the part of the transaxle that allows the driven wheels (in this case the front wheels) to rotate at different speeds while still applying power to both wheels. This is necessary because the outer wheel will travel a longer arc in turns, so the outer wheel will need to rotate more times to cover the extra distance. Art says the differential was invented by Leonardo da Vinci some 400 years before Ford started mass producing cars.

There are a few 3 piece caged needle thrust bearings that must be reassembled in the correct order and direction. TIS has good pictures of how they go back together.

Next we remove the drive chain that links the drive sprocket to the counter drive gear.

Now the drive sprocket that connects the drive chain to the ring gear.

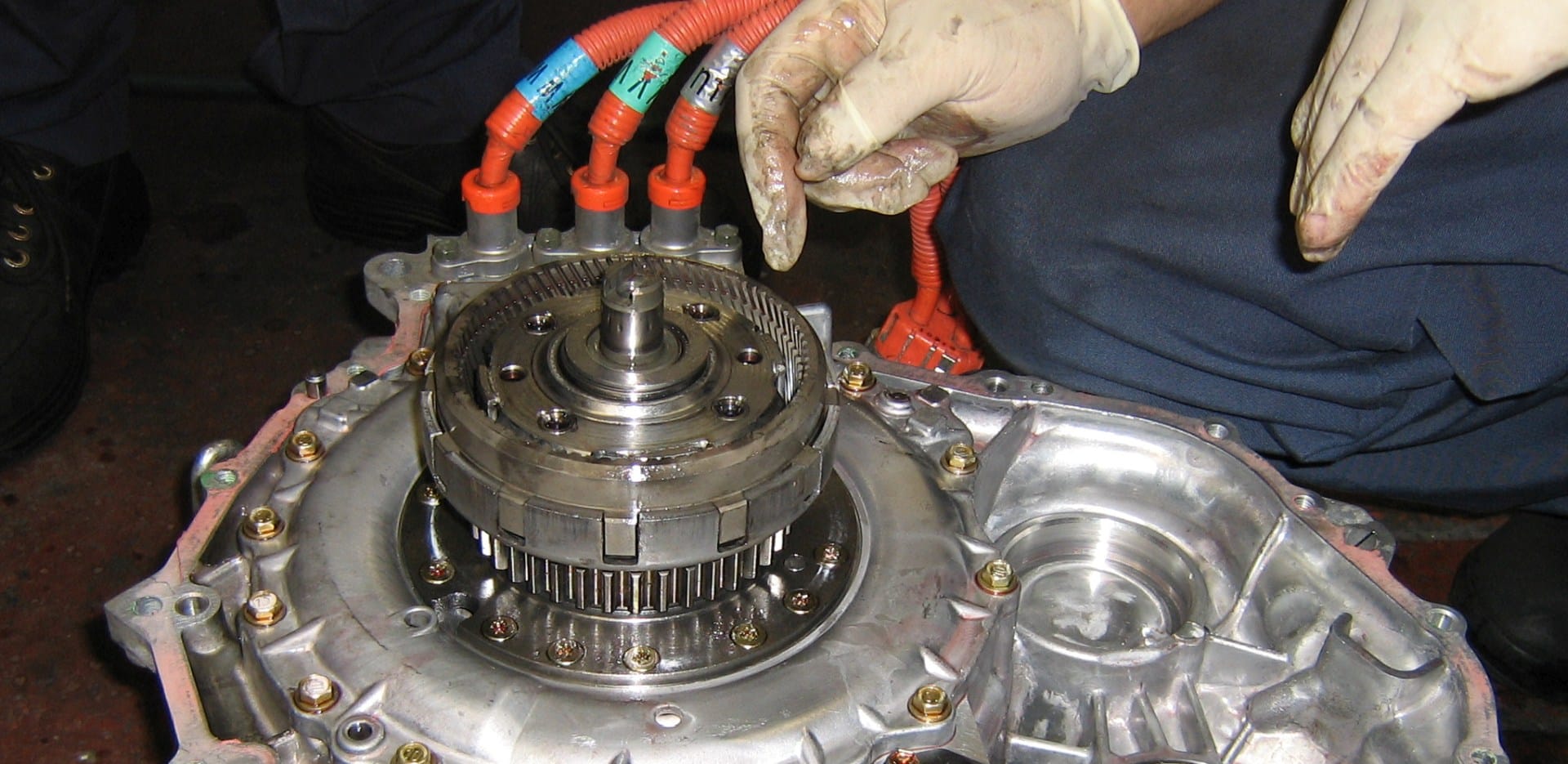

Next we remove the input shaft and attached planetary carrier assembly. The input shaft/planet gears are connected to the ICE (internal combustion engine) through a damper that looks sort of like a clutch disc. The planetary sun gear is also coming out with the input shaft, but it is connected to MG1 with the splines seen just below Scott’s hand.

And now the final piece of the planetary gear set, the ring gear, is removed. The ring gear is the output for this transaxle (or input during regen braking) and is permanently attached to the wheels via the chain & sprockets, counter gears, and differential.

The ring gear is also locked to the MG2 via these splines.

The counter drive gear is the last of the gears to be removed. Up until now, all of the bearings had been needle bearings, roller bearings, or bushings, and have been fairly easy to inspect visually. The counter drive gear has ball bearings and can not be visually inspected, so we check for any roughness. There is a little roughness, and bearings are cheap and easy enough to press off and on, so we order a set.

Next the transaxle oil pan is removed. We’re assuming that it will not come with the new MG2, and also want to check the magnet for metal chunks.

There is a bit of fine metal clinging to the magnet, but not enough to worry about. No larger chunks. We’ll wipe the magnet off and put it back into service.

This is the pick up tube screen. No metal embedded in here either. This probably won’t come with the MG2 either, so off it goes.

Eureka! The smoking gun! This may be why the transaxle failed in the first place. An assembly error! It took 81K miles for it to have an effect, but it looks like the oil pump pickup tube O-ring was cut on installation. Maybe there was a bit of flashing in the MG2 pickup tube hole that caught the O-ring on insertion.

We’re fairly sure the O-ring did not fail in service or when the pickup tube was removed because the broken O-ring end would be pointing the other way if it had been torn on the way out, or pulled in by the pump suction. The O-ring is stiff like plastic and frozen in this position, and I have no doubt it has been sitting like this for 6 years. Basically, this means the oil pump was sucking some air along with it’s T4 fluid, and may not have been able to provide adequate lubrication.

OK, back to the rest of the disassembly. The electrical connectors can be removed from the harness, and may not come with MG2, so we pull the 2 electrical connectors off and set them aside.

The parking detent spring comes out next.

Now the MG2 heat sink cover.

This is the MG2 heat sink. The red fluid is Toyota Long Life coolant, not T4. As you can see, there is not a whole lot of fin surface area, so I can’t imagine this does a lot to cool the MG2.

This heat sink is on the very top of the transaxle, and the inlet/outlet tubes go down six inches or so. This is a great spot for an air pocket. I imagine that this is one of the reasons the inverter coolant can be such a pain to bleed on the first generation Priuses. All the more reason to invest in an Air Lift if you plan to service the Prius!

I’m very tempted to call this the shift selector, but since this is a Prius, all this does is engage the parking pawl.

Time for the oil pump to come off the back side of MG2.

It doesn’t look too bad for an oil pump that’s been working with a broken pickup tube O-ring, but the scratching feels much worse than it looks in the picture, and an oil pump is cheap, so this Prius is getting a new one.

Those of you familiar with oil pumps will notice this is an extremely tiny oil pump! However, it makes sense when you think about it; there are no hydraulically actuated parts in the Prius, and most of the components are either sitting in oil or in a position to be lubricated by the splash.

A final bit of scavenging from the MG2. Since we are reusing all of the tapered roller bearings, we’ll need the bearing cups from the MG2 housing. We’ll also get the existing preload shims in the hopes that they will be correct for the new MG2 housing. Fat chance, but one can always hope.

We’ve gone about as far as we can go until the MG2 and other special order parts arrive. Time to mop up, pack up, and wait. You may be wondering about the judder and MG1. I figure the judder was all MG2 because: a) the judder was present in reverse, and MG1 isn’t doing anything in reverse, and b) all of the other gears and bearings have been inspected, and are OK.

A few days later…

The new MG2 has arrived, so we can measure to see what select fit bearing shims we will need to order for the four rotating assemblies supported between MG1 & MG2. Two of the assemblies, the differential and the counter driven gear, use taper roller bearings. Preload is critical on roller bearings. Too much preload (too tight) and there will not be enough room for a thin film of T4 fluid between the rollers and the races. With no oil film, the bearing will quickly overheat and fail. On the other hand, if there is too little preload, the assembly will be loose and clunk around.

We carefully inspect the oil pump pickup tube bore to make sure there are no sharp edges or anything else that might cause the new O-ring to tear. It looks fine.

We start with the differential carrier shim. The differential carrier is held with two tapered roller bearings. One in the MG1 side of the case, the other in the MG2 side of the case. When the MG2 is replaced, differences in machining tolerances must be corrected with shims inserted behind the bearing races

Now that we’ve installed the shim from the old MG2, we install the bearing cup on top of it.

This is the bearing cup & shim fully installed. You can see the “57” stamped on the shim. This is how Toyota identifies their shims. There is a chart in the manual that has the size for all of the different markings.

After coating the differential assembly with clean T4 fluid, we install it in the MG2 side of the case.

Next we lower the MG1 onto MG2.

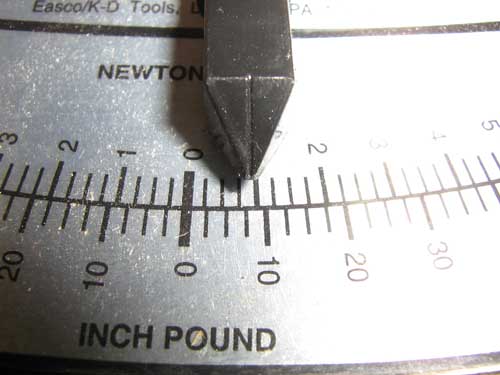

After tightening all of the case bolts, we use a very low range inch pound torque wrench to measure the torque (turning force) required to spin the differential assembly in the housing with no other components installed. If the torque is too great, we need to use a thinner shim to decrease preload. If the torque is too low, we need to use a thicker shim to increase preload. Our torque measurement met the specification, so we pull the cases apart to start the same process for the Counter Driven gear.

We install the shim for the counter driven gear from our old MG2.

And then the bearing race on top of it.

And drive it into place using an aluminum bearing driver (meaning a bearing driver made of aluminum, not a driver for aluminum bearings). We did this for the differential bearing race as well; I just forgot to take a picture.

This is the bearing race fully installed. The shim for the counter driven gear is completely hidden, so the mark can not be seen. This one was a “64”.

Now we install the differential again, followed by the counter driven gear. Both coated with clean T4 fluid.

On goes the MG1 side of the case.

Then we measure the torque required to turn both of the assemblies. We were not as lucky with the second measurement. The preload on the counter gear is too low! There is almost no change in the amount of turning force required to turn both assemblies. The manual offers the following tip: the torque will increase by approximately 10 inch/lb. for every .001″ of added shim thickness (in metric values of course, since we’re the only country foolish enough not to use the metric system). The current shim is a #64 (.0638″), so we order a #65 (.0646″), #66 (.0654″), and #67 (.0661″) from our dealer.

The other shimmed clearances are not checked using preload. Which is good, because hoisting the MG1 onto the bench and torquing all 27 case bolts to take a measurement gets old fairly quickly. We later realized that only 13 bolts needed to be torqued for the check. Doh!

To check the planetary gearset clearance, we must put all of its components into the MG1 side of the case.

First the input shaft assembly. The input shaft is welded to the back side of the planet carrier. The input shaft goes through the hollow sun gear, and then through a hole and into the bell housing where it connects to splines in the damper assembly on the gas engine. The sun gear has splines that project below the carrier into matching splines in the MG1 rotor.

Next the ring gear is installed. The outside of the ring gear is connected to the drive sprocket, which is connected to the drive chain, which is connected to the counter drive gear, which meshes with the counter driven gear, which finally meshes with the differential. The top of the ring gear is connected to the ring gear flange, which is splined to MG2. This means that any time the wheels are moving, MG2 is moving. They are permanently connected. There are no clutch packs or one-way rollers. This is why Toyota warns against towing the Prius with the front wheels on the ground.

Now we check the distance between the top of the planetary gearset to the MG1 case using a digital depth gauge and a straight edge. We use precision machined parallels for this (available at Enco, MSC, etc.). Most “mechanic’s” straight edges only have one machined surface. The parallel, as its name implies, has two surfaces, parallel and straight to within .0005″. It’s normally used for set up rather than measuring, but it works perfectly for this application. This one is exactly 1″ thick, making calculation easy.

We know the distance the planetary gearset protrudes from MG1 case joint surface from the previous measurement. Toyota calls this “Dimension A”. Now we check the room it has to protrude into the MG2 from the case joint. Toyota calls this “Dimension B” The difference between the two measurements is the thickness of the shim that should be used. Dimension B was 5.336″. Dimension A was 5.257″. The difference: .079″. The closest shim is a #6, which is is .0787″. The current shim is a #5, which is .7079″, so we had to order a #6 from our dealer.

The fourth and final shim adjustment is for the counter drive gear. The method for finding the proper shim is similar to the method for finding the input shaft shim. First we measure from the top of the counter drive gear to the MG1 case joint surface. “Dimension A” turns out to be .340″

Then we measure from the MG2 case joint surface to the counter drive gear bearing seat in MG2. “Dimension B” turns out to be .409″. The difference between B and A is the shim thickness, in this case .069″. The closest shim is a “J”, .0689″.

We’ve gone as far as we can go until we get the shims we’ve ordered. So everything goes back into boxes.

Twenty Five F#@king days later …

Well, we’ve been waiting for the three sizes of counter driven gear shims for 25 days now. Daily calls to our dealer and several “reships” and still no shims. We’ve grown desperate.

We have 3 junk Prius transaxles, one donated by a customer and two from jobs we’ve done. We opened all three to pull the counter driven gear shims. There are 29 possible sizes so there was only a 10% chance of the right shim being in one of the transaxles, but desperate times call for desperate measures.

If this were a movie, we’d heroically find the right shim and finally finish the job, but since it’s real life, we found three wrong sized shims, wasted a couple hours, and I ended up at the doctors office with an injured hand from helping Scott move these around (these are quite heavy, so you should use a hoist even when you are in a hurry). Well, I guess it wasn’t a complete waste. We discovered a neat trick for getting the drive sprocket needle bearing to line up quickly when joining the cases.

After another five days …

Well one of the shims we were waiting for is finally here. We received a 66, but not the 65 or 67. With fingers crossed, we install the shim, the race, the differential, the counter driven gear, and bolt up the cases.

Success! 17 inch pounds. It’s at the low end of the spec., but as my first auto shop teacher would always remind us, “It’s better to leave a tapered roller bearing a little too loose than a little too tight”. If we were to install the 67 shim, and the turning torque increased by 10 in/lb. it would be at the high end of the spec., so we’re finally ready to reassemble.

After double checking all of our previous measurements and shim calculations for the counter drive gear and the input shaft, it only takes 10 minutes or so to install all of the gearing.

There is a black link on the drive which must face up.

After a final check, Toyota’s orange FIPG (Form In Place Gasket) is applied to the carefully cleaned and degreased case joint.

Loctite is applied to all of the case joint bolts.

The case bolts are torqued to 18 ft/lb. Since torque wrenches are most accurate in the upper 80% of their range, we use an inch pound torque wrench set to 216 in/lb. We mark each bolt as we torque it, just to be sure none are missed.

Time to install the infamous oil tube O-ring.

When Scott tries to install the tube with the O-ring on it, he quickly realizes that it is VERY difficult to install this tube without the O-ring getting caught and bulging out the side. No matter how straight the tube is, the O-ring wants to get stuck. The only solution is a very gentle wiggling with light pressure.

Now we install a new input shaft seal.

And some fresh drive axle seals.

The new MG2 came with a sealed MG2 heat sink cover, parking shaft cover, and parking detent cover. So we did not need to reinstall any of this.

We reinstalled the oil pump shaft and new rotors and back cover. After some debate, I talked Scott into priming the oil pump with a small dab of Vaseline, despite no instructions to do so in the manual. I spent the first two years of my career working in transmission shops, and every builder I’ve known has prepared pumps this way. Common sense dictates a dab of Vaseline will do no harm, and I’ll feel better about its first dry start.

It’s done!

Now Scott reunites the transaxle with the ICE.

5 hours later, everything is put back together, the fluids are filled and bled, and every bolt is accounted for. Scott has realigned the wheels since the rack and subframe were out of the car. After clearing codes, nothing has reset. So far so good!

Time for a nice test drive around the neighborhood. No warning lights and perfect performance. I couldn’t be happier. Hopefully our customer’s joy at being reunited with her perfectly running car will drown out any memories of the month and a half of living without it.

Ready for delivery! The total bill is about 30% less than the whole transaxle jobs we’ve done. However, a rental car for 40 days might well cost a customer more than that.

Conclusion

The Prius HV transaxle is easier to rebuild than most transaxles. It should be an ideal profit center for us, since many shops are afraid of Hybrids and/or in-house rebuilding, but….

The parts are fairly expensive, and if there were enough problems with an HV transaxle, the cost of repair could easily exceed the cost of a brand new unit, making it a little risky to invest in a teardown.

And then there is the problem with parts availability. Any project that sits on a mechanic’s lift for a month or more will rob him of some productivity, irritate the customer, and loose the shop money.

Not a viable repair

This, very sadly, is the last Prius transaxle we’ll be overhauling. I could live with the possibility of wasting a couple hours tearing down an HV transaxle that turns out to be too badly broken to save. If that were the only issue, we’d be looking forward to doing the next one. The big problem is we just don’t have the space for a car to sit on a rack for more than a month.

Parts availablity is the main problem

I’m not sure why Toyota would have the MG2 available for purchase in the US, but not have the shims necessary for installing the MG2 anywhere but Japan. I also don’t understand why don’t they use carriers capable of delivering quickly and tracking their packages like FedEx or UPS to send small parts. WorldPac does it all the time. I’ll order a part from a warehouse 2000 miles away, and it will be in my hand the next day. Why wouldn’t the biggest car company in the world be able to do the same thing? Sure, Japan is 5000 miles away, not 2000, but surely parts could be sent in less that a week! It makes no sense to me.