This will be a quick look at the Subaru seat position sensor design, function, and diagnosis, without using the Subaru test harness / tool. If you’re working on an old Subaru with an airbag code 36, and you’re frustrated with Subaru’s lazy diagnostic procedure, which basically amounts to “Try a new one and if the code clears, you’ve found your problem”, you’ll probably find this page useful. If you’re looking for information about the services we offer, you can find it here.

What kind of sensor is the Subaru seat position sensor?

The Subaru seat position sensor is a two-wire hall effect sensor. Like all hall sensors its output changes when it’s exposed to a change in magnetic field. Two wire hall effect sensors change between two distinct current levels. The driver’s seat control unit provides a voltage through the sensor and measures the change in current in the circuit.

Here’s a datasheet that explains how a two-wire hall effect sensor works.

How does the driver’s seat control unit diagnose a problem with the seat position sensor?

Since the sensor has two current levels, the driver’s seat control unit can determine if the sensor is connected and working. If the current flowing through the circuit doesn’t match one of the two normal levels, there’s a problem with the sensor, wiring, or driver’s seat control unit.

What does the driver’s seat control unit output to the sensor?

This was a bit of a surprise. I was expecting a steady regulated voltage. Something below normal battery or charging system voltage like the frequently used 5V reference. What we found was something pretty different.

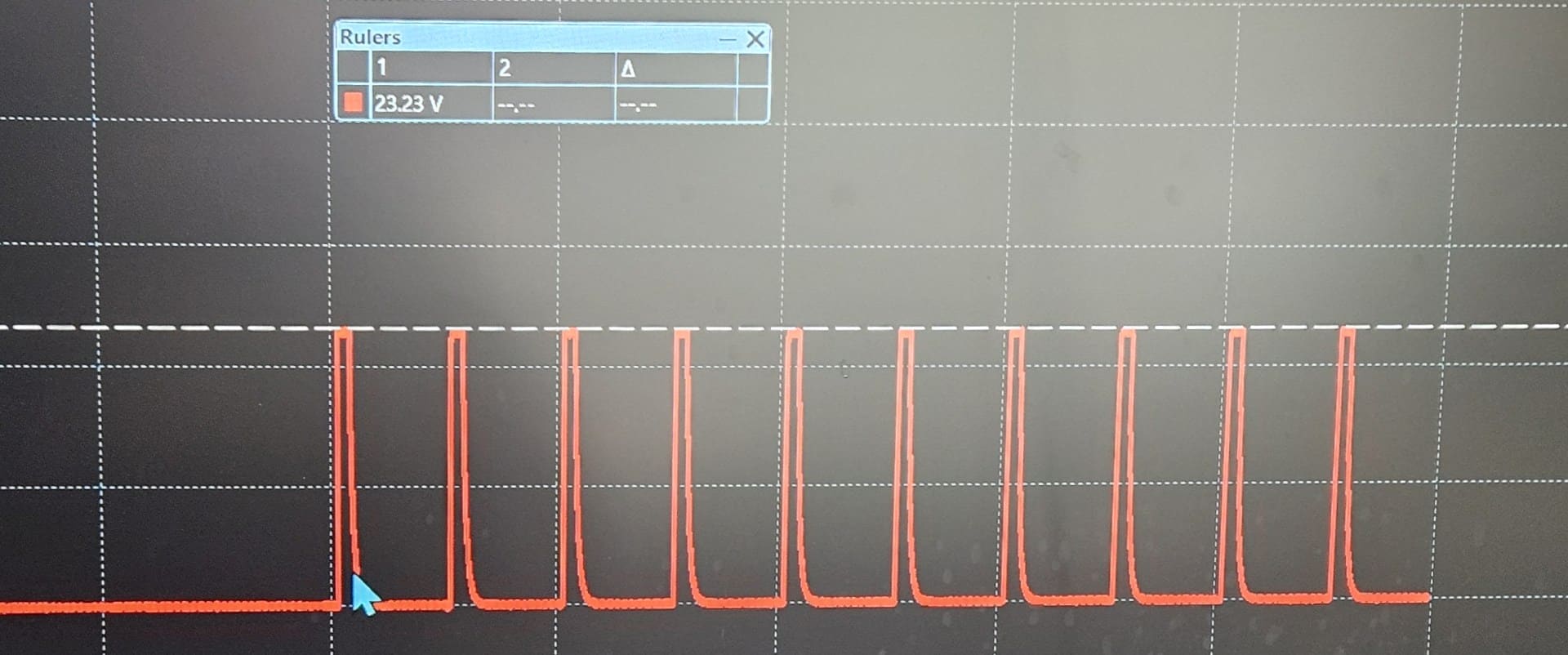

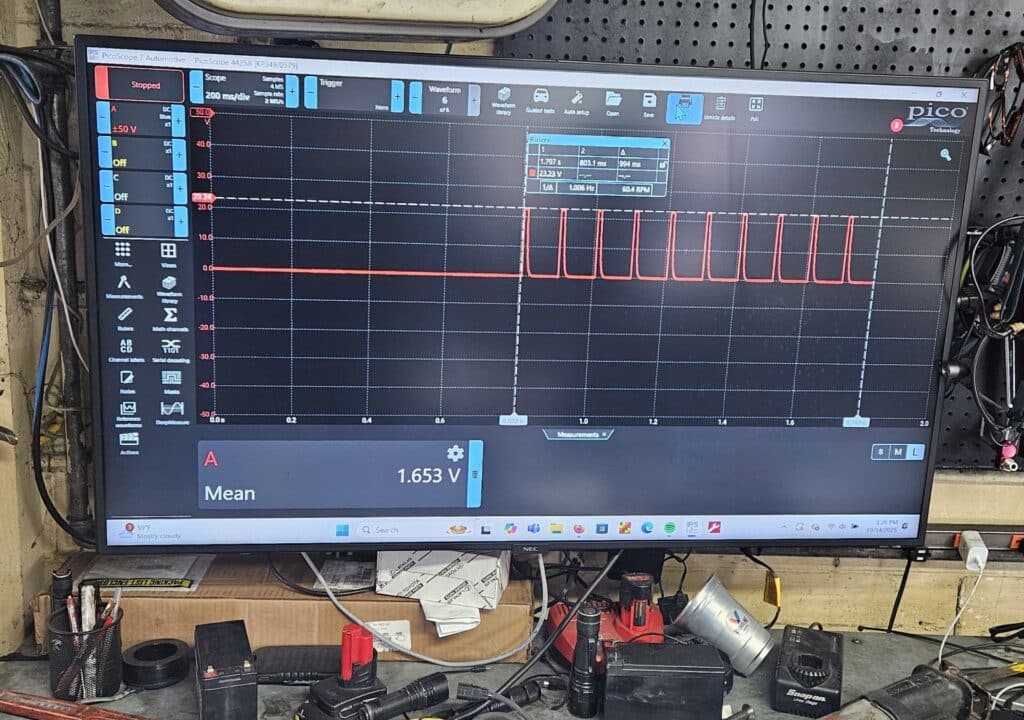

The driver’s seat control unit sends ~23V pulses to the hall sensor 10 times per second. If you measure with a DVOM, you’ll find it averages to around 1.6V, well below the working range list on the data sheets for two-wire hall sensors I found, but I assume the current is being measured during the on-time.

I’m sure there’s a reason for this that’s beyond my current understanding, but it doesn’t matter, once you know what to expect you can test. And as always, if Subaru doesn’t give you a specification, you can compare against known good.

What was the cause of the code 36?

We had a 2007 Subaru Outback with a code 36. The cause of the fault was a chafed insulation on both sensor wires where they pass above the seat rail, but it was actually kind of tricky to diagnose. We tried using Subaru’s method to start. Subaru recommends installing a test device onto the harness and then rechecking to see if the code 36 still sets. I’m sure that the test device is just a hall sensor on a pigtail harness, so we borrowed a sensor from another Subaru and installed it. The problem was fixed. It must be a bad sensor.

But wait. Didn’t I say the problem was the wiring? It was, but because the wires had been jostled a bit during the installation, the chafed wire were no longer shorted after installing the known-good sensor. Luckily it stopped working before the car left the shop or we ordered a replacement sensor.

This is why manufacturers should provide system descriptions rather than prescribing single use special tools 99% of mechanics won’t own. In this case Subaru’s documentation department could have cut and pasted from whatever sensor’s datasheet they used and added a paragraph explaining the control unit’s output and logic.

DIY Subaru seat position sensor simulator?

This project was more out of curiosity than a need to have one but it was hard to resist since you can buy a 2-wire hall effect sensor designed for automotive applications for just a couple bucks.

I’m not sure if this will actually work since these sensors are designed to switch between two specific current levels. Will the sensor I purchased have the same current levels as the one integrated into the seat sensor by Subaru? I don’t know. If I wanted to find out, repeating the test shown in the video with a known good sensor would be the way to find out.